+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

In the rapidly evolving landscape of manufacturing, OEM labeling and packaging systems stand at the forefront. Industry expert John Smith once noted, "Effective labeling is crucial for product success." This highlights how vital these systems are for product identity and market growth. Companies are increasingly aware of the importance of packaging that not only protects their products but also conveys powerful branding messages.

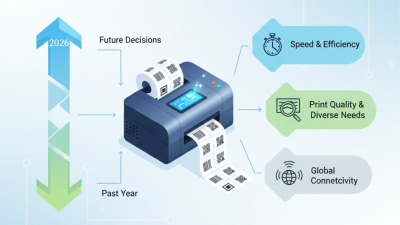

As we look ahead to 2026, the demand for innovative OEM labeling and packaging solutions is set to soar. Businesses must adapt to consumer preferences and regulatory requirements. Companies often struggle with outdated systems, leading to inefficiencies. There’s room for improvement, particularly in integrating technology with traditional practices.

The challenge lies in balancing design with functionality. Not every solution is perfect, and some systems may fall short of expectations. Reflection on past experiences can guide future innovations. In the end, the right OEM labeling and packaging systems can define a product’s success in a crowded marketplace.

OEM labeling and packaging systems play a crucial role in product presentation. These systems streamline the process of applying labels and packaging products efficiently. Manufacturers benefit from improved branding and consumer engagement.

Accuracy is vital in OEM systems. Mislabeling or packaging errors can be costly. Companies often struggle with maintaining consistent quality across batches. This inconsistency can lead to customer dissatisfaction and tarnished reputations. Investing in the right technology can help, but it requires careful evaluation of processes.

Automation is a significant advantage in labeling and packaging. It increases speed and accuracy. However, over-reliance on machines can sometimes overlook human insights. Employees' experiences can uncover potential flaws. Balancing automation with human oversight may yield better results. Continuous improvement should be a priority in every operation.

| System Type | Automation Level | Speed (units/min) | Labeling Accuracy (%) | Suitable Industries | Price Range (USD) |

|---|---|---|---|---|---|

| Automated Labeling System | High | 150 | 99.5 | Food, Beverage | $20,000 - $50,000 |

| Semi-Automatic Labeling | Medium | 70 | 98.0 | Pharmaceutical, Cosmetic | $10,000 - $25,000 |

| Manual Labeling System | Low | 30 | 95.0 | Retail, Crafts | $500 - $2,000 |

| Labeling and Packaging Combo | High | 200 | 99.0 | Manufacturing | $30,000 - $70,000 |

When evaluating OEM labeling and packaging systems for 2026, several key features deserve attention. Efficiency stands out as a primary concern. Reports indicate that companies can reduce packaging costs by up to 25% through optimized systems. Streamlined operations enhance productivity, ensuring faster turnaround times in production. Many firms are leaning toward automation to handle repetitive tasks. This shift not only minimizes human error but also boosts overall accuracy.

Flexibility in packaging options is also vital. A recent survey highlighted that 70% of businesses prioritize adaptable systems that cater to varying product sizes and materials. Customization capabilities allow companies to meet diverse market demands efficiently. However, there are challenges. Some systems may lack compatibility with existing equipment, leading to unforeseen costs. Companies should carefully assess these compatibility issues before investing heavily.

Sustainability is another crucial element in 2026. Modern consumers increasingly favor eco-friendly packaging solutions. Statistically, about 60% of consumers are willing to pay more for sustainable options. Yet, the industry still struggles with balancing cost and environmental impact. Manufacturers need to reconsider their approaches to avoid falling behind. Overall, evaluating these features will significantly influence the success of OEM solutions in the coming years.

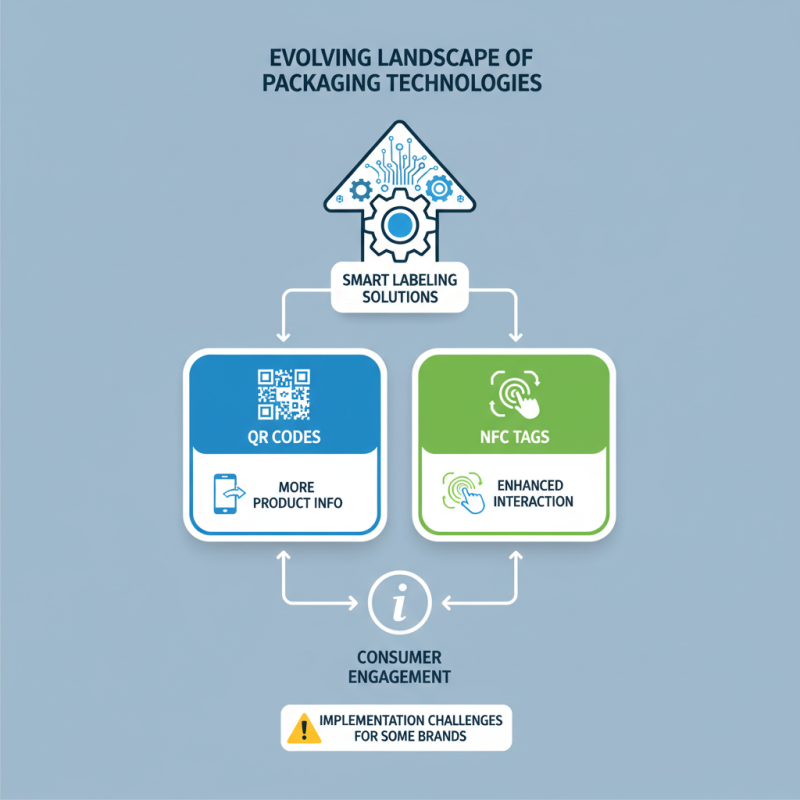

The landscape of labeling and packaging technologies is evolving rapidly. Companies are leaning towards smart labeling solutions. These include QR codes and NFC tags. Such innovations provide consumers with more product information. They enhance user interaction with the product. Yet, some brands may struggle to implement these technologies effectively.

Sustainability is another critical trend. Eco-friendly materials are gaining popularity. Many businesses face challenges in sourcing sustainable options. The shift toward biodegradable packaging is significant. However, the cost and accessibility can be problematic. Not every company finds these alternatives affordable.

Customization is increasingly in demand. Consumers want personalized products. This pushes manufacturers to rethink their packaging strategies. In some cases, they may overlook details like practicality. How to balance aesthetics and functionality remains a concern. The path ahead is not straightforward, but it offers exciting possibilities.

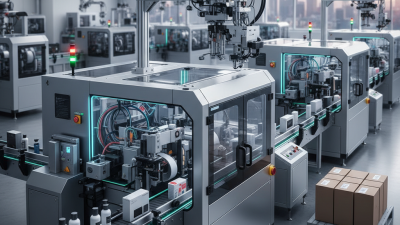

As 2026 approaches, the demand for advanced OEM labeling and packaging systems grows. Companies seek efficiency, accuracy, and innovation to stand out in a crowded market. Not every vendor meets these needs, though. Some still rely on outdated technologies. Businesses must consider this as they explore options.

When evaluating vendors, it’s crucial to look at their technology. Automated systems can enhance productivity. But are they reliable? Some systems may have frequent downtimes. This can hinder operations and affect timelines. Consumers also demand sustainability in packaging. Vendors not focusing on eco-friendly practices may struggle to keep up.

Moreover, user experience can vary widely. Some vendors may offer great tech but lack customer support. Others excel in service but have less effective solutions. Businesses should assess these aspects carefully. Visiting trade shows can provide insights into emerging vendors. Engaging with peers also helps identify successful partners, as word-of-mouth remains powerful in this industry.

This chart represents the distribution of various labeling and packaging systems preferred by manufacturers in 2026 based on their efficiency and technology integration.

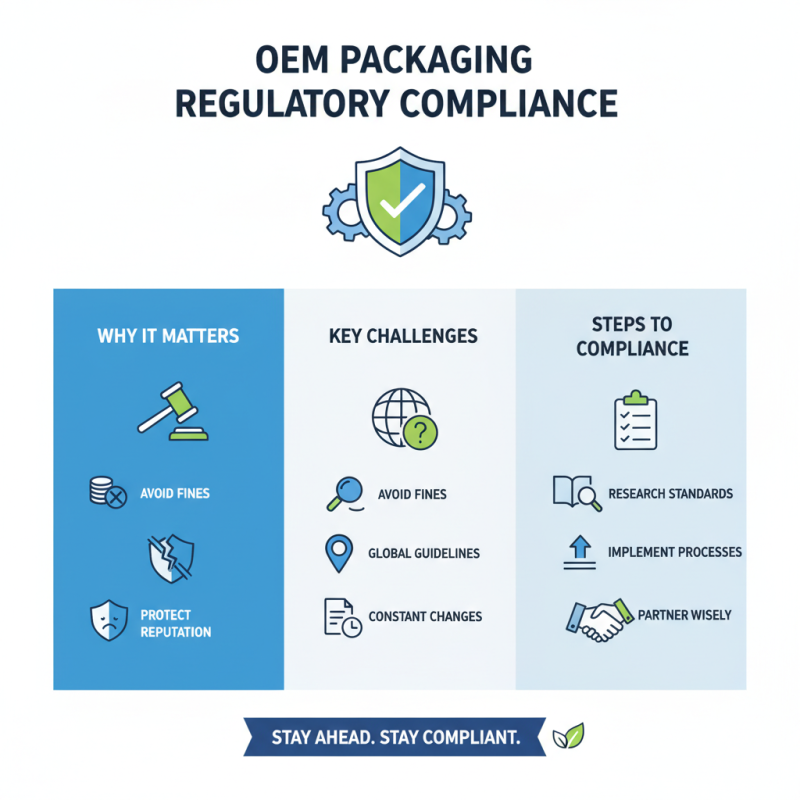

Regulatory compliance in OEM packaging is crucial. Companies must understand the guidelines that govern their products. Failing to meet these standards can lead to fines and damaged reputations. Different regions have unique requirements. It's important to research these thoroughly before launching a product.

Tips: Always keep documentation updated. Ensure that labels contain accurate information. Misleading labels can lead to legal issues. Regular audits of packaging processes can identify gaps in compliance. Compliance training for staff is essential.

Packaging design can also influence compliance. Clear labeling promotes transparency. It allows consumers to make informed choices. However, some companies overlook this fact. They might focus too much on aesthetics. Beauty shouldn't overshadow the need for accurate information.

Tips: Engage with regulatory experts. Their insights help in meeting compliance requirements. Consider hiring consultants to guide the process. Being proactive can save time and money in the long run. Regularly review changes in regulations to stay ahead.