+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

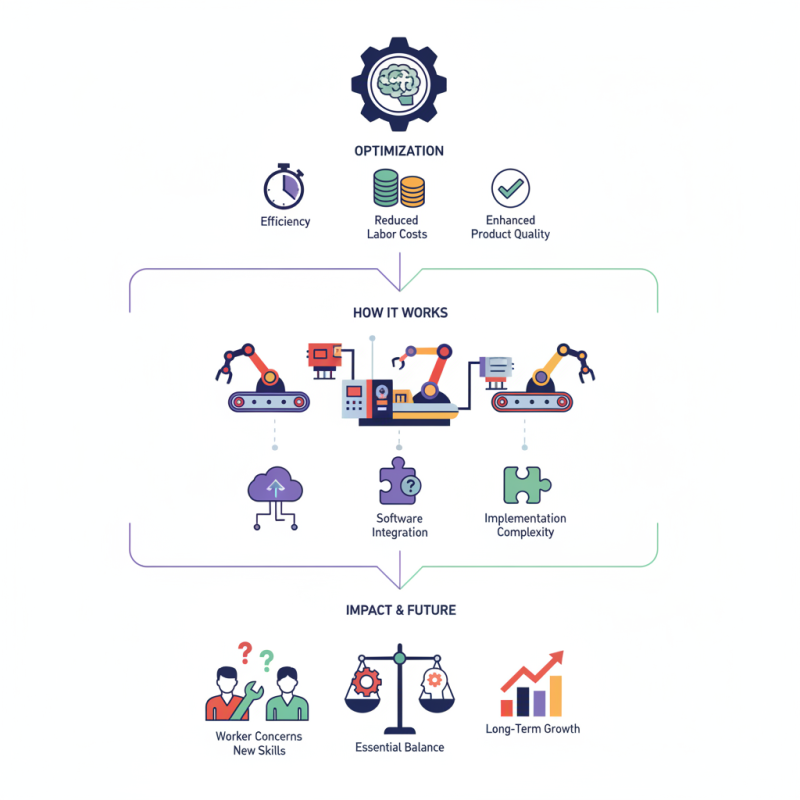

Automated Production Line Equipment is revolutionizing manufacturing. According to Dr. Emily Carter, an expert in industrial automation, "Efficiency in production will define the future." This innovative technology optimizes processes, reduces labor costs, and enhances product quality.

Understanding how Automated Production Line Equipment operates is crucial. These systems integrate machinery and software to automate various production stages. Each component works in harmony, yet the implementation can be complex. Manufacturers must weigh the benefits against potential challenges.

Despite its advantages, the shift to automation raises concerns. Not all workers embrace the change. Some fear job loss or the need for new skills. Companies must address these anxieties while focusing on long-term growth. This balance is essential for a successful transition into the world of automated production.

Automated production line equipment refers to systems designed to manufacture products efficiently. These systems integrate various machines, robots, and software. The goal is to streamline production and reduce human intervention. They can handle tasks such as assembly, inspection, and packaging. This equipment is flexible, adaptable to different product types.

In a typical setup, conveyors transport materials while robotic arms perform specific tasks. Sensors monitor the process in real-time, ensuring quality control. Often, the integration of artificial intelligence improves efficiency. However, the reliance on technology poses challenges. Breakdowns can halt production entirely, leading to losses. Regular maintenance is essential for smooth operation.

While automated production lines enhance speed and accuracy, they require skilled operators. Training staff can be time-consuming and requires continuous effort. Moreover, the initial investment can deter small businesses. The benefits must be weighed against these challenges. Thus, a careful approach is necessary when adopting this technology.

Automated production lines are essential for modern manufacturing. They increase efficiency and reduce labor costs. Key components of these lines include conveyor systems, robotics, and control systems. Conveyor systems transport materials between workstations. They can be adjustable and automated to fit different production needs.

Robotic arms are another crucial element. They handle tasks like assembly, welding, and packaging. These robots operate with precision, often achieving error rates below 1%. Data from industry reports suggest that automation can boost productivity by up to 30%. However, integrating robots requires careful planning. Misalignment between equipment can lead to downtime.

Control systems manage the entire production process. They collect data, monitor operations, and make real-time adjustments. Selecting the right software is vital for seamless operation. Tips: ensure all components are compatible before installation. Regular maintenance can prevent unexpected failures. Keep the system updated to leverage the latest advancements in automation technology. Optimization is an ongoing effort, and it’s essential to review processes frequently.

| Component | Function | Common Materials Used | Typical Applications |

|---|---|---|---|

| Conveyor Systems | Transport materials between different stages of production | Steel, plastic, rubber | Automotive assembly, packaging |

| Robotic Arms | Automated manipulation and assembly tasks | Aluminum, steel, various composites | Electronics, assembly lines |

| Sensors | Monitor conditions and operational status | Plastic, metal | Quality control, safety systems |

| Control Systems | Manage and coordinate all machinery | Various electronic components | Manufacturing automation |

| Assembly Workstations | Place where manual or semi-automated assembly occurs | Wood, plastic, metal | Final assembly of products |

Automated production lines operate by utilizing a combination of machinery and technology to streamline manufacturing processes. Each piece of equipment plays a specific role, working together to enhance efficiency. For instance, robotic arms can assemble products with precision, while conveyor belts transport items smoothly across the production floor. This harmonious interplay between machines reduces the time needed for production.

However, the implementation of automated lines isn't without challenges. Sometimes, machinery can malfunction or require adjustments. This can lead to unexpected downtimes. Workers must be trained to handle these situations promptly. Automation also raises questions about employment. While some jobs may be eliminated, new roles emerge in monitoring and maintenance.

Many industries are integrating automation, but it's important to continuously reflect on its impact. Efficiency gains are impressive, yet businesses must stay adaptable. At times, reliance on technology can backfire, especially if systems are not regularly updated. Understanding both the benefits and drawbacks is crucial for sustainable growth.

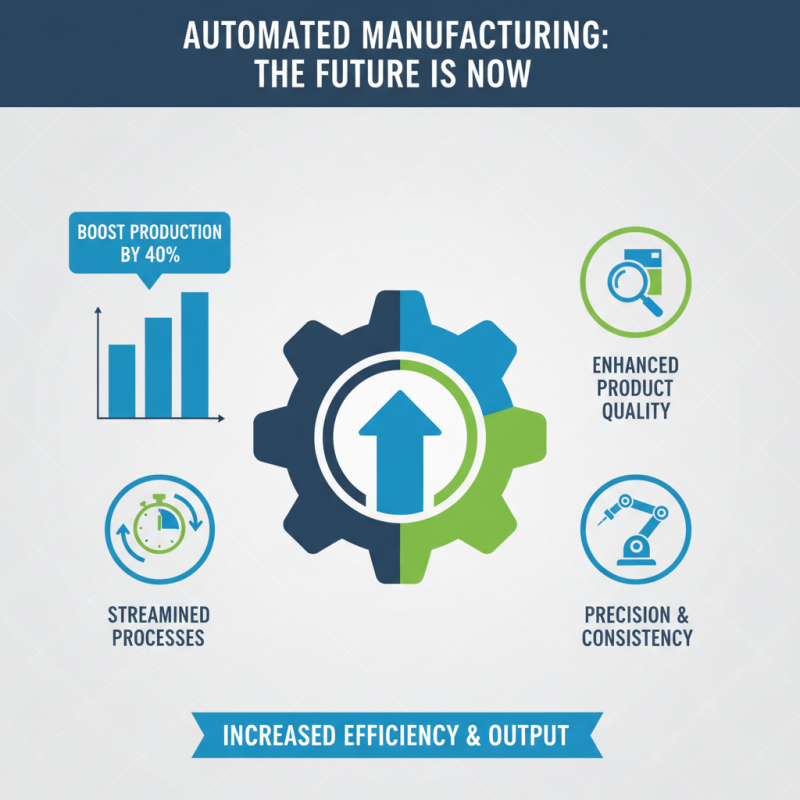

Automated production line equipment has transformed manufacturing. This technology streamlines processes and increases efficiency. Recent studies show that companies utilizing automation can boost their production rates by up to 40%. These improvements often lead to enhanced product quality. Precision machines perform tasks more consistently than human workers.

One major advantage of this equipment is cost reduction. Businesses can lower labor costs significantly. A report by a leading industry analyst indicates that automated systems can cut operational expenses by 20-30%. This allows companies to reinvest in other areas. However, initial setup costs can be a barrier for some smaller manufacturers. They may hesitate to embrace automation fully.

Despite the clear benefits, challenges remain. Training staff to work alongside automated systems is crucial. Some employees resist change, fearing job loss. Nevertheless, with proper training, they can take on new roles. Automation can aid human workers, not replace them. Balancing technology with human touch is vital in this transition. The path forward requires careful planning and adaptation.

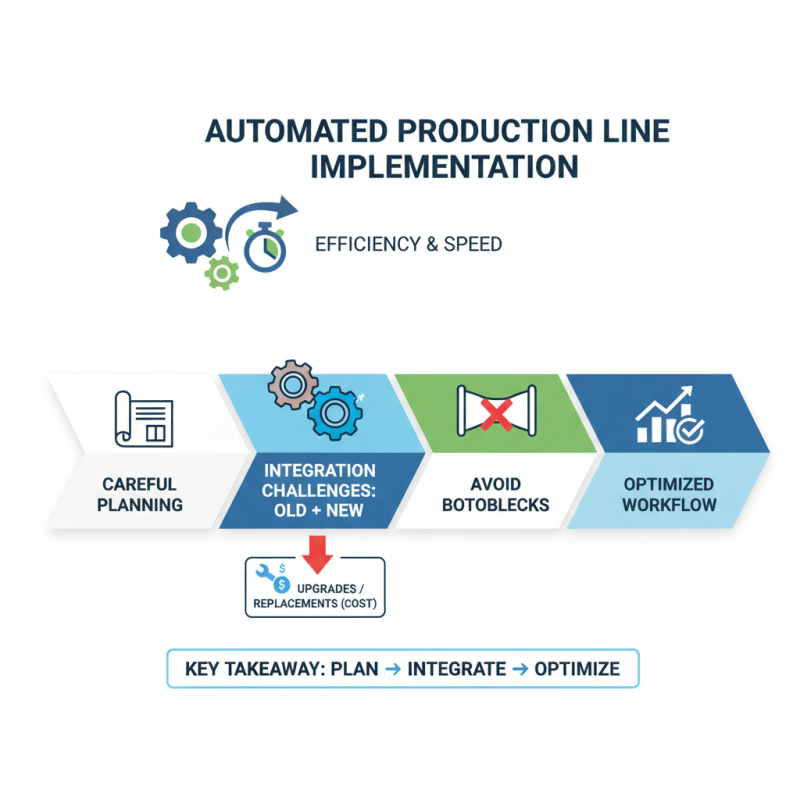

Automated production lines promise efficiency and speed, but implementation comes with challenges. Each step in the process must be carefully planned to avoid bottlenecks. For instance, integrating old machinery with new technology can cause compatibility issues. This often requires additional resources for upgrades or replacements.

Staff training is crucial yet often overlooked. Workers need to understand the new systems to operate them safely. Many employees may resist change, leading to delays. Adaptation takes time and patience. Clear communication helps ease these transitions. It's essential to involve the team early in the process.

Moreover, maintenance poses an ongoing challenge. Equipment can fail unexpectedly, halting production. Regular check-ups and proactive measures can mitigate this risk. However, unforeseen issues will still arise. This unpredictability can disrupt schedules and plans. Balancing innovation with practicality is key to a successful automated production line.