+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

An Automatic Barcode Label Printer is essential for many businesses today. These printers simplify product labeling and inventory management. With advancements in technology, finding the right printer can be overwhelming.

In this review guide, we will explore the best options available in 2026. We will look into features that matter. Print speed, quality, and ease of use are crucial. Some printers may fall short in durability or technical support. Users should consider their specific needs carefully.

Choosing an Automatic Barcode Label Printer requires thought. Each brand has unique strengths and weaknesses. This guide aims to provide clarity. We'll discuss popular models along with their pros and cons. By the end, readers should feel better equipped to make informed decisions. The right printer can enhance efficiency and accuracy in labeling tasks.

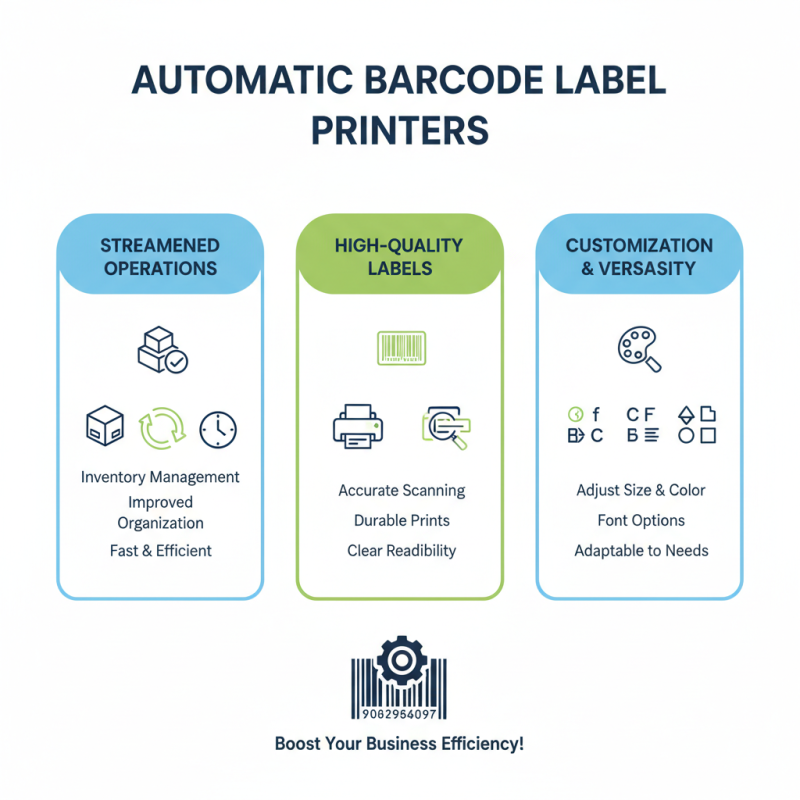

Automatic barcode label printers have become essential tools in various industries. These printers streamline inventory management and improve organization. They produce high-quality labels quickly and efficiently, essential for businesses that deal with large volumes of products or shipments. Users can often customize the labels, adjusting size, color, and font. The versatility is appealing, but it's vital to match the printer type with specific needs.

While many printers offer impressive features, not all are easy to operate. Some models come with complicated interfaces that can frustrate new users. It often takes time to get familiar with the settings. Moreover, the initial costs can be daunting. Companies should consider ongoing expenses for supplies and maintenance. In some cases, this could lead to unforeseen budget issues.

Despite the challenges, the advantages of automatic barcode label printers outweigh the drawbacks for many users. These devices enable businesses to operate smoothly and maintain accuracy in labeling. For those struggling with labels, it's important to evaluate which features truly benefit their workflow. Investing time in understanding printer capabilities may lead to a more efficient and productive environment.

When selecting an automatic barcode label printer, there are several key features to remember. First, consider print speed. A faster printer saves time, especially in busy environments. Look for printers that can produce labels quickly without compromising quality. A label printed too slowly can disrupt workflow.

Another crucial feature is resolution. Higher resolution delivers sharper, clearer barcodes. This clarity prevents scanning errors and ensures accuracy. Testing the resolution on various label materials can highlight potential issues. Also, think about connectivity options. Some printers connect via USB, while others may support wireless connections. Choose a printer that fits your needs.

Durability is often overlooked. A sturdy printer can endure daily use and last longer. Consider the materials used in the printer's construction. A machine that feels flimsy may require more repairs over time. Take note of user reviews. They often reveal insights about performance and reliability. This process may feel daunting, but careful consideration pays off.

In the search for the best automatic barcode label printers of 2026, user ratings play a crucial role. Models vary widely, leading to different user experiences. Some printers excel in speed, while others are celebrated for ease of use. A few have innovative features that users adore. Yet, performance can vary based on specific tasks. Not every model is perfect for all businesses.

User feedback highlights common strengths and weaknesses. Many users appreciate durability in long-term usage. However, some report issues with ink smudging or inconsistent printing quality. It’s essential for potential buyers to check these reviews closely. Performance is not always what it seems on paper. Factors like print volume and label type significantly influence results.

Specific models may shine in one aspect but falter in another. Frequent breakdowns or software glitches have been reported. These concerns lead to frustration. It’s important to weigh user ratings against individual needs. Even the best models have areas for improvement. Identifying the right balance can enhance overall satisfaction in the long run.

When considering barcode label printers, two categories dominate: budget and premium models. Budget printers typically cost less but may compromise on speed and print quality. A study by the Research and Markets indicates that budget printers often have a lower resolution, typically around 203 DPI. This might be acceptable for basic applications. However, businesses that require high-quality labels may find this lacking.

On the other hand, premium barcode printers offer better features. They can print at higher dpi, often reaching 300 or even 600 DPI. This ensures clarity and durability in various environments. According to a survey from TechValidate, 72% of users reported increased efficiency with premium models due to faster print speeds and enhanced connectivity options. However, the entry cost for these printers can be steep, sometimes exceeding $1,000. This presents a dilemma for smaller businesses. They must balance initial investment against long-term needs.

In terms of total cost of ownership, it's also worth examining maintenance expenses. Budget printers may need replacement parts sooner. This could inflate overall costs over time. Conversely, premium models often have longer lifespans and better reliability. Yet, their higher price tag can lead to stress for businesses on tight budgets. Making the right choice requires careful consideration of both upfront costs and future needs.

This chart compares the average costs of budget and premium automatic barcode label printers based on various features and performance ratings.

Maintenance is vital for automatic label printers to guarantee optimal performance. Regular cleaning prevents dust and ink buildup that can affect print quality. Use a soft cloth for the exterior and a cleaning solution designed for printers. This simple step extends the life of the printer. Check the printer's manual for specific maintenance guidelines.

Support options should also be considered. Many manufacturers offer online resources and customer service. It’s useful to know how to access help if issues arise. This includes troubleshooting tips or software updates. However, sometimes support lines can be slow. This can lead to frustration. Prepare for potential delays by having a backup plan in place.

It's important to routinely check for worn-out parts. Print heads and rollers can degrade over time. These parts may require replacement to maintain quality. A proactive approach saves time and reduces costs in the long run. Neglecting upkeep can lead to larger problems down the line. Regular monitoring is key to keeping your printer in prime condition.