+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

In the fast-paced world of manufacturing and packaging, efficiency is crucial. High-Speed Automatic Label Applicators have emerged as essential tools in this sector. They streamline the labeling process, significantly reducing time and labor costs. With various models available, finding the right applicator can be overwhelming.

These machines promise speed and precision, but is that enough? Many businesses grapple with the transition to automation. Equipment can be expensive upfront. There are concerns about reliability and learning curves. Evaluating each applicator’s specifications and features is vital to ensure optimal performance.

Investing in High-Speed Automatic Label Applicators should be carefully considered. The demands of your production line can dictate which models suit best. Balancing cost, speed, and quality leads to better outcomes. Let's explore the top options for 2026 that enhance efficiency while addressing common industry challenges.

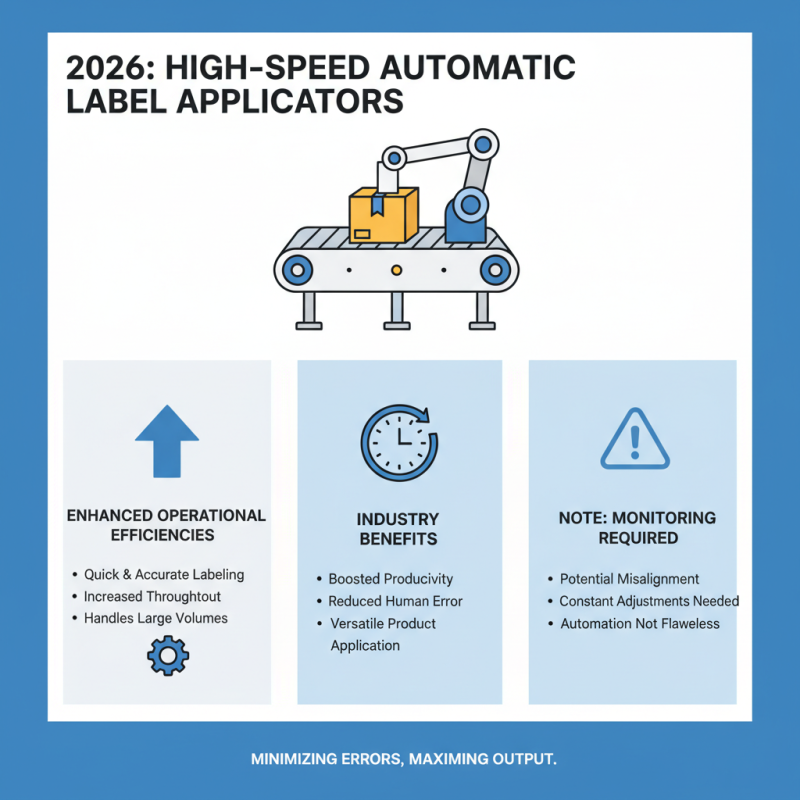

In 2026, high-speed automatic label applicators will play a crucial role in enhancing operational efficiencies. These machines are designed to apply labels quickly and accurately on various products. Industries will benefit from increased productivity as these applicators can handle large volumes at high speeds. The automation minimizes human error, but it is not flawless. Occasionally, misalignment can occur, which demands constant monitoring and adjustments.

These applicators will vary in features, including sensor technology and application methods. Different products may require tailored solutions. This presents a challenge in selecting the right applicator for specific tasks. Users will need to assess their unique needs carefully. While many machines promise seamless operation, some may fall short in actual performance. It is essential to reflect on the long-term investments for efficiency gains versus potential operational hiccups.

As the industry evolves, the blend of speed and precision remains critical. High-speed automatic label applicators will be integral to supply chains, ensuring products are labeled legibly and efficiently. Companies will need to embrace continuous learning and improvements as they adopt these technologies. The road to optimizing labeling solutions includes evaluating successes and setbacks along the way.

When looking for high-speed automatic label applicators, key features can make all the difference. Speed is essential; a machine that can apply labels quickly saves time and boosts productivity. Look for models that can handle various label sizes and types. This flexibility allows for diverse applications without the need for frequent adjustments.

Consider the ease of operation as well. Some machines appear user-friendly but can have hidden complexities. An intuitive interface is crucial for minimizing errors during use. Maintenance requirements also matter; machines that are difficult to maintain may lead to downtime, which affects overall efficiency.

Integration with existing systems is another factor. Some machines may not easily connect with your workflow, creating additional challenges. Always check for compatibility to avoid future issues. Lastly, don’t overlook after-sales support. A good support system can mitigate problems quickly, ensuring that your labeling process runs smoothly. Balancing these features might be challenging, but thorough research can lead to better decision-making.

In the world of packaging, high-speed automatic label applicators have become essential. These machines streamline the labeling process for various industries, ensuring efficiency and precision. Production lines benefit significantly from rapid labeling. However, choosing the right model is critical. Many models boast impressive speeds, but speed alone does not guarantee reliability.

Consider the user interface and maintenance requirements. Some high-speed applicators are complex, making them difficult to operate. A straightforward setup can enhance productivity. Also, many models struggle with different label sizes and materials. This flexibility is crucial for businesses that handle diverse products.

Investing in high-speed applicators can be daunting. Users should evaluate their specific needs carefully. The initial cost may be high, but the return on investment can be substantial. However, ongoing support and service are vital to maximize uptime. Some brands excel in customer support; others do not. Finding a balance between speed, efficiency, and support is essential for optimal performance.

The demand for high-speed automatic label applicators is growing in various industries. A recent report indicates that these machines can increase labeling efficiency by up to 50%. Choosing the right model is crucial for cost-effectiveness. A cost analysis showed that some advanced models deliver a quicker return on investment. However, upfront costs may deter some businesses despite long-term savings.

Tip: Always calculate total costs. Include maintenance, labor, and material use in your assessments. A lower initial price might not mean savings in the end. Some models also require special training, adding hidden costs.

Performance varies significantly among different applicators. One study found that speed does not always correlate with accuracy. Some machines perform well in high-speed scenarios but produce misalignments. These factors often lead to wasted materials and increased operational costs.

Tip: Pilot test before full implementation. This helps identify potential issues in real-world conditions. Understanding your specific needs is vital. Balancing speed and accuracy can significantly impact overall efficiency and profitability. Take the time to assess various options carefully.

| Model | Speed (Labels/Min) | Accuracy (%) | Cost (USD) | Warranty (Years) |

|---|---|---|---|---|

| Model A | 300 | 99.5 | 2500 | 2 |

| Model B | 250 | 98.7 | 2300 | 3 |

| Model C | 350 | 99.0 | 2700 | 1 |

| Model D | 400 | 97.8 | 3200 | 2 |

| Model E | 280 | 99.2 | 2100 | 5 |

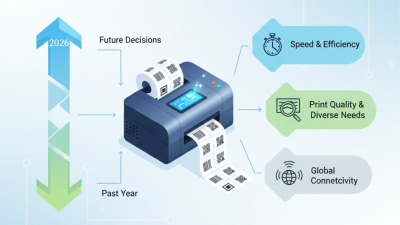

In the evolving world of labeling technology, high-speed automatic label applicators are on the frontline. These machines have enhanced productivity across industries. However, there are still areas for improvement. For instance, the integration of AI could be a game changer. It's crucial to consider how smart systems can adapt to various product types and shapes.

Future trends suggest a push toward greater automation. As we incorporate more sensors, label applicators will become more intuitive. They could reduce waste and improve accuracy. But there's a learning curve. Training operators on these advanced systems may initially slow down production. The balance between speed and efficiency remains a work in progress.

Sustainability is an essential focus as well. The materials used for labels impact environmental footprints significantly. Innovating with biodegradable options can lead to positive industry changes. However, finding a cost-effective way to implement these solutions is a challenge. The technology is advancing, but addressing these hurdles is vital for the future of label applicators.

This chart illustrates the market share distribution of different technologies used in high-speed automatic label applicators as of 2026. The data shows a significant trend toward advanced automation and integration in labeling systems.