+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

In today's rapidly evolving packaging industry, selecting the right Automatic Labeling Systems Exporters is crucial. According to a recent market report by Smith & Associates, the global labeling machinery market is projected to reach $4 billion by 2026, reflecting a 5% annual growth rate. This underscores the significance of choosing high-quality exporters who provide reliable, state-of-the-art labeling systems.

Expert in packaging solutions, Dr. Jane Thompson, emphasized, "The right labeling system can significantly enhance production efficiency." Her insight resonates deeply within the industry, especially as companies strive to improve workflows and reduce costs. Quality exporters can offer advanced technologies tailored to specific production needs, ensuring compliance with both domestic and international standards.

However, the decision-making process can be complex. Many businesses face challenges in evaluating the capabilities of different exporters. Factors such as warranty terms, support services, and technology upgrades often remain overlooked. Over-reliance on cost alone can lead to poor choices. Ensuring a balance between value and quality is essential for long-term success.

When selecting automatic labeling systems exporters, certain factors play a crucial role. Begin with their experience in the market. A company that has been in the industry for several years usually understands the nuances of various labeling needs. Newer companies might lack this insight. Check their range of products. A diverse lineup can indicate adaptability to different industry requirements.

Consider customer service as well. Efficient communication is key when resolving issues. Prompt support can save time and resources. Look for exporters who offer training. This ensures your team knows how to operate the systems effectively. It's not just about selling a machine; it's about empowering users.

Don't forget to evaluate their technology. The latest advancements can enhance efficiency. However, newer technologies may come with steep learning curves. Balance innovation with practical usability. Some exporters might have flashy options but lack practical application. Reflect on your specific needs to find the right fit. This process can be daunting, but focusing on these factors helps make an informed decision.

This bar chart illustrates the evaluation factors considered when selecting automatic labeling systems exporters in 2026. The factors include Technology, Customer Support, Price, Delivery Time, and Quality which are critical for making informed decisions.

Automatic labeling systems come in various types, each suited for different packaging needs. These systems can be categorized based on their application and features. For example, there are systems designed for labeling bottles, boxes, and even pallets. Each type serves a unique purpose, requiring careful consideration in the selection process.

One popular type is the tabletop label applicator. It’s efficient for small to medium-sized businesses. These systems are easy to operate and can handle a range of product sizes. However, they might struggle with higher volumes. Another type is the fully automatic label applicator. It can greatly increase productivity, but it often requires a higher investment. Finding a balance between cost and efficiency can be tricky.

When evaluating these systems, consider factors like labeling speed, accuracy, and maintenance needs. Not every company has the same requirements. Sometimes, a less sophisticated system might be more suitable. Be careful not to overlook ongoing support and service from suppliers. The wrong choice can lead to downtime and inefficiency.

When evaluating the quality standards of automatic labeling systems from exporters, attention to detail is essential. Look for systems that comply with international quality certifications. These certifications ensure that the products meet safety and efficiency benchmarks. It's crucial to verify these standards to avoid dealing with subpar equipment.

Consider the materials used in the labeling systems. High-quality components often lead to improved durability and performance. Check if the exporters provide transparent information about their sourcing methods. This transparency reflects their commitment to quality and ethical practices.

Tips: Always request samples to test the systems before making a large purchase. Pay attention to the labeling speed and precision. Ask other users for their experiences. Their insights can reveal hidden strengths or weaknesses. Sometimes, even reputed exporters can fall short in certain areas. It's wise to remain skeptical and do thorough research before making a commitment.

| Exporter Location | System Type | Max Speed (Units/Hr) | Labeling Accuracy (%) | Standards Compliance | Warranty (Years) |

|---|---|---|---|---|---|

| North America | Automatic Linear | 120 | 99.5 | ISO 9001 | 2 |

| Europe | Rotary | 150 | 99.8 | CE Marking | 3 |

| Asia | Flexible | 100 | 99.0 | ISO 14001 | 5 |

| South America | Sleeve | 90 | 98.5 | FDA Compliant | 2 |

| Africa | Print and Apply | 80 | 97.0 | SABS Certified | 1 |

When selecting an automatic labeling systems exporter, after-sales support is crucial. Reports indicate that over 80% of clients prioritize service quality. Exporters with robust support networks often boost customer satisfaction significantly. It is vital to check if they offer training and technical assistance as standard.

A survey revealed that 65% of businesses faced challenges after installation due to insufficient guidance. Simple inquiries can lead to delays when there is no dedicated support. Efficient response times matter greatly. Companies with response times under four hours typically retain higher client loyalty.

While some exporters claim excellent service, not all deliver. Look for reviews and case studies that highlight real experiences. Transparency in communication about service offers is essential. Engage with the exporter’s support team before making a decision. This step can reveal much about their reliability.

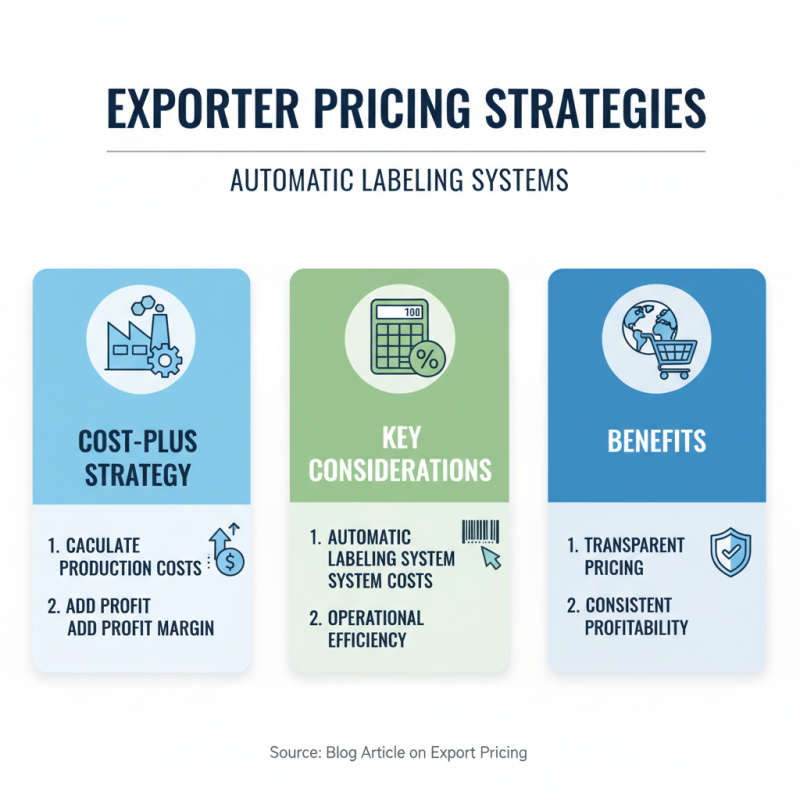

When choosing automatic labeling systems exporters, pricing strategies are crucial. Many exporters employ different methods to determine their prices. Some adopt a cost-plus strategy. They calculate the production costs and add a margin. This strategy can lead to a straightforward pricing model.

Others focus on value-based pricing. They consider the benefits provided to customers. This can reflect higher prices due to advanced technology. However, it may not resonate with all buyers. Some companies may feel overpriced, even with added value. Pricing transparency remains a critical issue. Staying informed about market trends is essential.

Lastly, dynamic pricing is common. Exporters adjust prices based on demand and competition. This strategy can maximize profits but might confuse customers. For instance, a sudden price hike could turn potential buyers away. Understanding these strategies helps in making informed decisions. The right choice can lead to better outcomes for your labeling needs.