+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

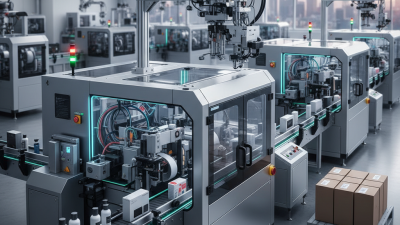

Choosing the right Automatic Weigh-Price Labelling Machines can be challenging. These machines play a crucial role in modern retail and manufacturing. They streamline operations and improve efficiency. However, with many options available, making a decision is not straightforward.

When selecting an Automatic Weigh-Price Labelling Machine, consider your specific needs. What products will you label? How much volume do you handle daily? These questions will guide your choice. Look for features like speed, integration capabilities, and ease of use. Some machines are too complex for basic tasks, which can lead to frustration. The ideal machine should feel intuitive.

Many businesses overlook the maintenance aspect. Regular upkeep is essential for consistent performance. Neglecting this can lead to downtime and loss of productivity. Reflect on how often you can maintain the machine. Balancing cost, functionality, and reliability is key to making the right investment.

Automatic weigh price labelling machines are crucial for many businesses. They improve efficiency and accuracy in product labeling. According to industry reports, over 70% of retailers use these machines to enhance labeling speed. This is vital in today’s fast-paced market where accuracy is expected.

Understanding the features of these machines can be challenging. Many come with various functionalities, like price updates and weight measurement. However, not all models offer the same performance. A study indicated that around 30% of users experienced issues with label adhesion. This reflects the importance of researching before purchase.

Maintenance is another aspect to consider. Regular upkeep is necessary for optimal performance. Some machines require specific cleaning solutions that can be costly. In fact, almost 40% of users overlook this, leading to malfunctions. It's essential to evaluate total operating costs when selecting a machine.

When selecting an automatic weigh price labelling machine, consider key features that enhance efficiency.

Accuracy is paramount. Machines should weigh products correctly and label them precisely.

This ensures pricing is consistent and avoids customer confusion.

Another important feature is speed. High-volume operations need machines that can handle numerous items quickly.

Look for models that can label multiple products simultaneously. This can save time and reduce labor costs.

Tips: Assess the machine’s user interface. A friendly, intuitive design makes it easier for staff to operate.

Training time will be shorter. Also, check for maintenance requirements. Some machines may need frequent servicing, while others are built for longevity.

Consider connectivity features too. Machines that integrate with inventory systems can streamline operations.

They reduce manual data entry errors. In the end, weigh the pros and cons of each option.

Some choices may seem ideal but may not meet long-term needs.

Think about future expansions and upgrades.

When selecting an automatic weigh price labelling machine, accuracy and precision are critical factors. A report from the Packaging Machinery Manufacturers Institute (PMMI) indicates that precision can vary by up to 5 grams in some machines. This could lead to significant pricing errors, negatively impacting profit margins. Errors result in overcharging or undercharging customers, creating trust issues.

Achieving high accuracy in labelling is essential for businesses. According to a study by the National Institute of Standards and Technology (NIST), a 1% inaccuracy in weight can lead to losses of thousands of dollars annually. Businesses should assess machines' calibration processes. Regular checks can maintain standards. However, many operators overlook this. They might rely too heavily on machine outputs without verifying weight measurements.

Furthermore, the design of the label and how it adheres to products affects customer perception. If labels are misapplied due to machine errors, this can lead to confusion. A poorly applied label may even discourage purchases. Precision in labelling machines goes beyond just weight; it encompasses clarity and adherence. Regular maintenance, timely recalibration, and staff training are vital steps that companies must not ignore.

When looking for the best automatic weigh price labelling machines, evaluating brands and manufacturers is essential. Start by researching companies that specialize in labeling technology. Consider their history in the industry. Longevity often indicates reliability. Look for manufacturers with positive customer feedback. Testimonials can reveal a lot about their quality and service.

Tips: Always check online reviews. They can highlight quirks in machines. Don’t solely rely on flashy marketing. Sometimes, the most promoted brands may not live up to expectations. Attend trade shows to see machines in action. Hands-on experience can help make a more informed decision.

It’s important to reflect on your specific needs. What features matter most to you? After all, not every machine suits every business. Focus on compatibility and user-friendliness. Sometimes, complicated models promise too much but can be frustrating to use. Reach out to industry peers to gather insights. Real-world experiences can guide your choice effectively.

This chart represents the evaluation of various automatic weigh price labelling machines based on key performance indicators such as Speed (labels per minute), Accuracy (percentage), and Reliability (mean time between failures in hours).

When considering the purchase of an automatic weigh price labeling machine, budgeting is crucial. Evaluate your financial limits. Understand that prices can vary significantly based on features and capabilities. A basic model might suffice for small businesses, while larger operations may require advanced machines. Think about the long-term savings from automation. While initial costs can seem high, reduced labor costs can justify the investment.

It’s essential to account for additional costs. Installation fees, maintenance, and the cost of supplies can add up. You may need software updates and training for staff members too. These hidden expenses can catch you off guard, leading to overspending. Reflect on your business needs and how often the machine will be used. Will it be used daily or occasionally? This decision directly impacts your return on investment. Misjudging usage can lead to wasted resources.

Lastly, don't forget to consider financing options. Explore leasing or loans that spread payments over time. This may ease the initial financial burden. Remember, choosing a machine is a significant decision. Gather quotes, examine features, and listen to user experiences. Take your time to decide wisely.

| Feature | Description | Estimated Cost ($) | Budgeting Tips |

|---|---|---|---|

| Speed of Labeling | Speed of the machine, measured in labels per minute. | $2,000 - $10,000 | Calculate based on your production needs. |

| Label Size Compatibility | Different machines support various label sizes. | $500 - $2,500 | Ensure it fits your label dimensions. |

| Printing Technology | Thermal, inkjet, or laser printing technologies. | $1,000 - $5,000 | Consider long-term printing costs. |

| User-Friendliness | Ease of setup and operation for staff. | $300 - $1,500 | Choose machines with intuitive interfaces. |

| Maintenance Requirements | Level of regular maintenance needed. | $200 - $1,000 annually | Factor in ongoing service agreements. |