+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

In the dynamic world of packaging, International Labeling Equipment Suppliers play a crucial role. They provide essential tools for industries needing effective labeling solutions. According to Alex Thompson, a renowned expert in the field, "Labeling is not just about compliance; it's about conveying trust." This statement highlights the importance of quality in labeling equipment.

The suppliers collaborate with manufacturers to ensure that products meet stringent regulations. Their services often extend beyond just selling machinery. They offer consultations to optimize labeling processes. Many businesses, however, still struggle to find the right supplier that fits their needs. This mismatch can lead to inefficiencies in production.

Moreover, the technology used by International Labeling Equipment Suppliers constantly evolves. While some companies embrace these advancements, others lag behind. This gap raises concerns about staying competitive in the market. Equipment that fails to meet modern standards can hinder a brand’s reputation. Thus, businesses must reflect on their labeling strategies and the suppliers they choose. Quality and innovation are no longer optional; they are essential for success.

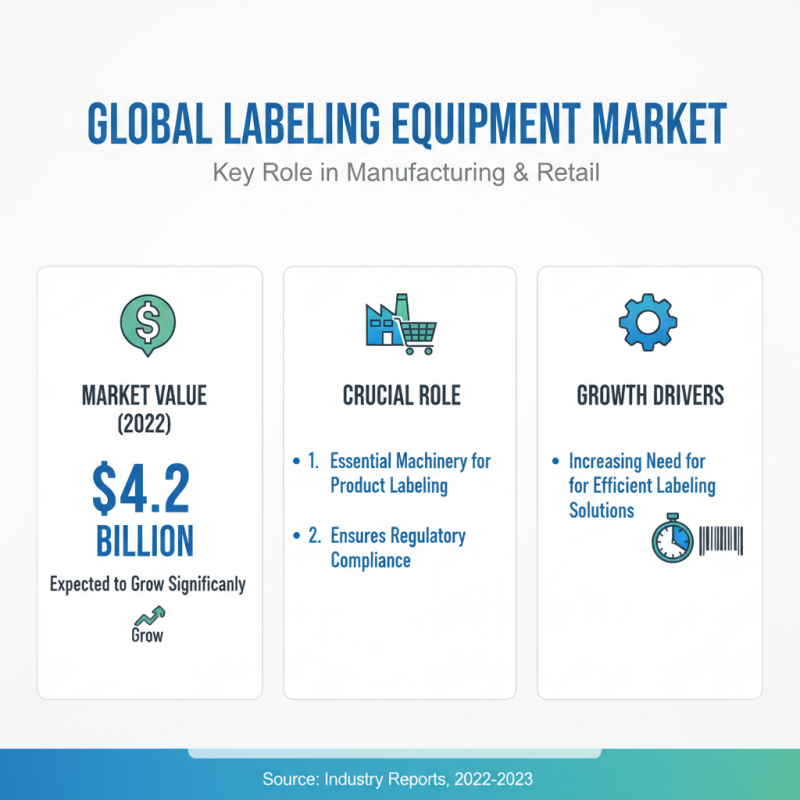

International labeling equipment suppliers play a crucial role in manufacturing and retail sectors. They provide essential machinery for labeling products, ensuring compliance with regulations. The global labeling equipment market was valued at approximately $4.2 billion in 2022 and is expected to grow significantly. This growth is driven by the increasing need for efficient labeling solutions.

These suppliers operate by offering a range of products. They provide automatic, semi-automatic, and manual labeling solutions. Each type of equipment serves different business needs. For instance, automatic labeling machines suit high-production environments, while manual machines cater to smaller facilities. Reports suggest that automatic machines account for nearly 60% of market demand due to their efficiency.

However, challenges exist within the industry. Some suppliers struggle with maintaining consistent quality amid rising competition. Additionally, the rapid technological advancements can lead to obsolescence, forcing companies to innovate constantly. Manufacturers often face difficulties in adapting their equipment to new materials or applications, which can impede growth. Addressing these issues is vital for suppliers to remain relevant in the dynamic global market.

Labeling equipment suppliers play a crucial role in various industries, providing essential tools for product identification and compliance. They offer a range of machinery to meet diverse labeling needs. Some of the most common types include label printers, applicators, and dispensers. According to industry reports, the labeling equipment market is projected to grow by over 4.6% annually, underscoring the demand for efficient labeling solutions.

Label printers are vital for custom labels. They allow businesses to create labels on demand, enhancing flexibility. Applicators and dispensers automate the labeling process. This increases speed and accuracy in production lines. A 2022 survey indicated that 62% of companies experienced efficiency gains by using these technologies. Automated equipment can reduce labor costs but may involve higher upfront investments.

However, selecting the right equipment can be challenging. Variations in label materials, sizes, and printing techniques add complexity. Some suppliers may not fully understand their clients' needs, leading to mismatches and inefficiencies. It's essential for businesses to assess their unique requirements before committing to a supplier. Knowledge gaps can result in lost time and resources.

International labeling equipment suppliers play a crucial role in various industries. They provide the tools necessary for efficient labeling of products. These suppliers operate by sourcing materials, creating machinery, and ensuring quality control. Each supplier has its unique approach to meet customer needs.

In this competitive market, international suppliers must adapt constantly. They analyze trends and respond with innovative solutions. Suppliers often face challenges like fluctuating demand and material shortages. These hurdles can affect their operational efficiency.

Tip: Always check for updated technology trends. Keeping up with advancements can give suppliers a competitive edge.

Effective communication with clients is essential. This includes understanding client requirements and providing tailored solutions. Miscommunication can lead to delays, impacting overall productivity. Some suppliers may struggle with this aspect.

Tip: Regular feedback from clients can enhance service quality. It can help identify areas needing improvement.

Maintaining supply chain integrity is another vital aspect. Suppliers deal with various partners, from manufacturers to logistics teams. A breakdown in any part of this chain can lead to significant issues. Some suppliers may overlook this, risking their operational success.

The chart above displays the market share percentage of international labeling equipment suppliers across different regions. Asia leads the market with a significant share, followed by North America and Europe. South America and Africa have smaller shares, reflecting the varying levels of demand and supply in these markets.

Labeling equipment suppliers play a crucial role in various industries. They provide equipment that automates the labeling process. Key markets include food and beverage, pharmaceuticals, and retail. These industries rely on precise labeling for compliance and branding.

In the food and beverage sector, accurate labeling ensures consumers receive essential information. This includes ingredients, nutrition facts, and expiration dates. For pharmaceuticals, labeling must meet stringent regulations. It is crucial for patient safety and effective dosage. Retailers often use labeling for promotions. Eye-catching labels attract consumers and drive sales.

Despite their importance, labeling operations can face challenges. Sometimes, equipment fails to meet the specific needs of a unique product. Suppliers may struggle with compatibility issues. Additionally, the rapid pace of technology can lead to outdated practices. Suppliers must constantly refine their offerings. This ensures they remain relevant in a competitive landscape. Continuous improvement is vital for both suppliers and their clients.

| Market/Industry | Key Applications | Types of Labeling Equipment | Region |

|---|---|---|---|

| Food and Beverage | Product labeling, ingredient information | Automatic labeling machines, adhesive labelers | North America |

| Pharmaceuticals | Prescription labels, dosage information | Print and apply systems, tamper-evident labelers | Europe |

| Cosmetics | Branding labels, ingredient disclosures | Wrap-around labelers, sleeve labelers | Asia-Pacific |

| Consumer Goods | Packaging labels, promotional materials | Custom label printers, digital label applicators | Latin America |

| Chemicals | Hazard warnings, handling instructions | Heavy-duty labelers, industrial label printers | Middle East & Africa |

International labeling equipment suppliers face multiple challenges in a competitive market. They operate in an environment that demands high efficiency and precision. Sourcing quality materials can be a hurdle. It often leads to delays and increased costs. Suppliers must also ensure that their products meet various international standards. Regulations differ between countries, complicating compliance.

Moreover, technology is ever-evolving. Staying updated is critical yet challenging. Many suppliers struggle to invest in the latest innovations. This affects their competitiveness. Training staff to handle new equipment can drain resources. Some suppliers may not allocate enough time for training, leading to mistakes.

Another significant challenge is maintaining customer satisfaction. Timely deliveries are essential, but logistics can be unpredictable. Unexpected transportation issues may arise, causing frustration for clients. Building strong relationships is key, yet, it is often overlooked. Suppliers must find a balance between costs and quality. Ignoring this can mean losing clients to competitors.