+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

In today’s fast-paced manufacturing environment, the importance of efficiency cannot be overstated. Companies are continually seeking ways to streamline their operations, reduce costs, and improve product quality. One of the critical areas that contribute significantly to these goals is the use of Precision Labeling and Packaging Machines. These advanced machines play a vital role in ensuring that products are labeled correctly and packaged efficiently, which not only enhances the aesthetic appeal but also ensures compliance with regulations and consumer expectations.

Precision Labeling and Packaging Machines are designed to meet the diverse needs of various industries, from food and beverage to pharmaceuticals and consumer goods. The integration of cutting-edge technologies into these machines enables high-speed labeling and packaging processes while maintaining remarkable accuracy. This results in reduced waste, faster turnaround times, and increased productivity. As businesses aim to optimize their production lines, the adoption of these machines becomes essential for maintaining a competitive edge in the market.

By leveraging the capabilities of Precision Labeling and Packaging Machines, manufacturers can not only improve their operational workflows but also boost customer satisfaction. The seamless combination of precision labeling and efficient packaging contributes to a more effective supply chain, allowing companies to respond swiftly to market demands. Therefore, understanding the significance of these machines is crucial for any organization looking to enhance its production efficiency and overall business performance.

In the fast-paced world of production and packaging, precision labeling machines have become crucial for ensuring efficiency and accuracy. According to a recent market analysis by Smithers Pira, the global labeling market is expected to reach $50.56 billion by 2024, driven largely by advancements in labeling technologies. Leading manufacturers are increasingly investing in automation and digital solutions, enhancing labeling speed and reducing errors, which aligns with the industry's trend towards higher productivity and reduced waste.

One of the standout technologies in precision labeling is the use of high-resolution inkjet printing and laser marking. These methods not only afford precise label placement but also offer the flexibility to print variable data, such as QR codes and barcodes, on-demand. With the rise of e-commerce and the need for better traceability, this capability is proving essential. The demand for efficient labeling has led to an adoption rate of over 35% for automated labeling machines in sectors such as food and beverage, pharmaceuticals, and cosmetics, according to a report by Research and Markets. This trend underscores the critical role that precision labeling plays in maintaining compliance with regulatory standards while meeting consumer demands for faster delivery times.

This chart illustrates the production efficiency of various top precision labeling machines measured in units per hour. The data showcases the comparative performance of different models in the market, emphasizing their capabilities in enhancing production efficiency.

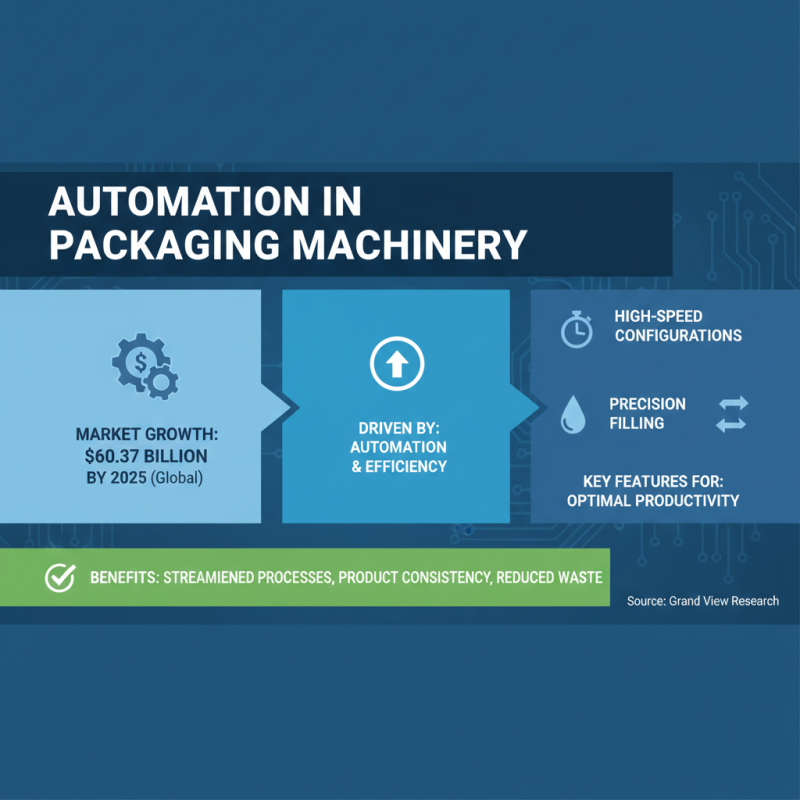

In the fast-paced landscape of modern production lines, efficient packaging machines play a critical role in ensuring operational success. According to a report by Grand View Research, the global packaging machinery market size is expected to reach $60.37 billion by 2025, driven largely by the demand for automation and efficiency in manufacturing. Packaging machines that incorporate advanced features such as high-speed labeling, precision filling, and flexible configurations are essential for achieving optimal productivity. These machines not only streamline processes but also enhance product consistency and reduce waste.

Key features of modern packaging machines include smart technology integration, which allows for real-time data monitoring and predictive maintenance. Research from MarketsandMarkets highlights that the predictive maintenance market within the manufacturing sector is projected to grow from $2.4 billion in 2020 to $10.5 billion by 2025, underscoring the importance of operational efficiency. Additionally, machines designed with multi-functionality enable businesses to adapt to varying product sizes and packaging styles quickly, thereby reducing downtime and increasing overall throughput. Emphasizing automation and precision, these packaging solutions contribute to the agility needed in today's competitive market, allowing manufacturers to meet fluctuating consumer demands effectively.

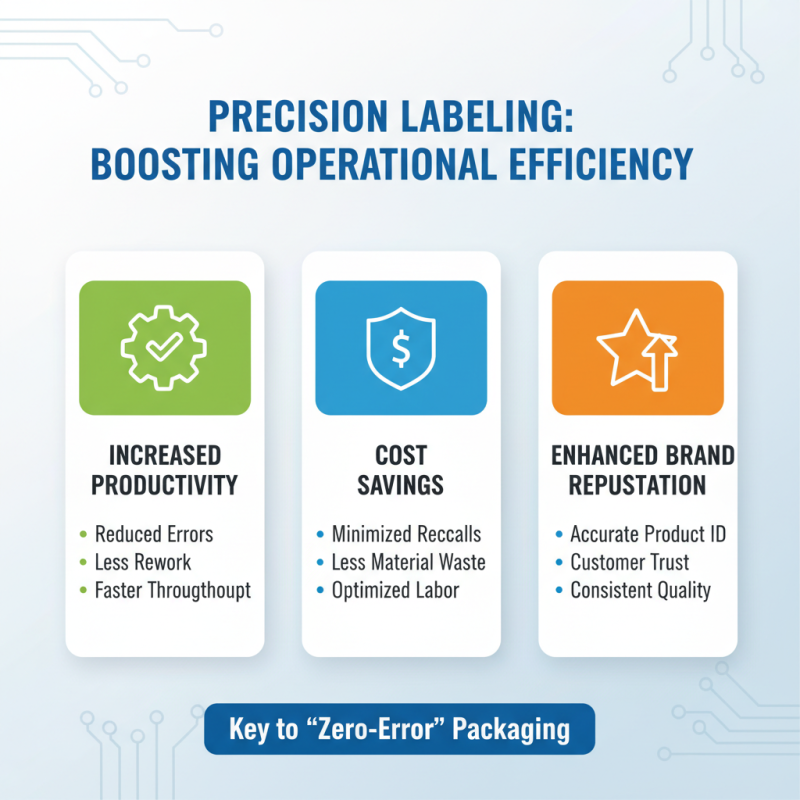

Precision labeling plays a critical role in enhancing overall operational efficiency and controlling costs in production settings. By employing advanced labeling technologies, manufacturers can dramatically reduce the likelihood of errors during the packaging process. Accurate labels ensure that products are correctly identified, minimizing the risk of recalls or mislabeling, which can lead to significant financial losses and damage to brand reputation. As a result, companies benefit from increased productivity, as employees spend less time rectifying mistakes and more time focusing on value-added activities.

Moreover, the integration of precision labeling machines can streamline workflows and optimize supply chain management. By automating the labeling process, businesses can achieve higher throughput rates, which directly impacts their bottom line. This automation not only enhances speed but also reduces labor costs, enabling companies to allocate resources to other critical areas of their operations. The precise application of labels also contributes to compliance with safety regulations and industry standards, further safeguarding the business against potential fines and regulatory challenges, thereby ensuring long-term profitability and sustainability.

The labeling and packaging machinery market is undergoing significant transformation, driven by innovations in technology and rising demand for automation. As industries seek to enhance efficiency and reduce operational costs, the adoption of precision machinery has surged, allowing for faster production rates and improved accuracy in labeling. Market research indicates a robust growth trajectory, with projections estimating a substantial increase in market value over the next few years. Factors contributing to this growth include the expansion of e-commerce, heightened consumer demand for attractive packaging, and an increasing focus on sustainability in production processes.

Emerging trends in the market highlight the shift towards smart and integrated systems that can seamlessly operate within existing production lines. As manufacturers invest in these advanced technologies, they are not only improving their output but also meeting stringent quality standards. Enhanced functionalities such as real-time monitoring and data analytics are becoming commonplace, allowing companies to respond swiftly to market changes.

Furthermore, the trend towards eco-friendly packaging solutions is encouraging the development of machinery that minimizes waste and optimizes resource usage, aligning with global sustainability goals. With these dynamics in play, the labeling and packaging machinery sector is well-positioned for continued expansion in the foreseeable future.

In the ever-evolving landscape of manufacturing, companies are increasingly turning to advanced labeling solutions to streamline their production processes. Case studies reveal that organizations adopting precision labeling machines have not only improved efficiency but also enhanced product visibility and compliance with industry standards. For instance, a beverage manufacturer implemented a fully automated labeling line, resulting in a 30% increase in output and a significant reduction in labeling errors. This transition allowed the company to meet rising consumer demand while ensuring accuracy and consistency.

When considering the implementation of advanced labeling solutions, it's vital to assess your specific production needs and challenges. One key tip is to conduct a thorough analysis of your current labeling process to identify bottlenecks or areas for improvement. Investing in the right technology can lead to notable gains in productivity and cost efficiency. Another important tip is to prioritize flexibility in labeling systems, as this allows for quick adjustments to accommodate different product sizes and labels without major downtime.

Moreover, successful case studies demonstrate the importance of employee training alongside technology upgrades. Ensuring that your team is well-versed in operating the new machinery can mitigate potential issues and further optimize production. By fostering a culture of continuous improvement, businesses can fully realize the benefits of advanced labeling solutions and stay competitive in the market.

| Machine Type | Efficiency Rate (%) | Speed (units/hour) | Key Features | Implementation Outcome |

|---|---|---|---|---|

| Automatic Labeling Machine | 98 | 500 | High-speed operation, Precise labeling | Reduced labeling errors by 30% |

| Semi-Automatic Packaging Machine | 95 | 300 | User-friendly interface, Versatile packaging options | Increased production capacity by 20% |

| Labeling and Coding Machine | 97 | 400 | Integrated coding, Compact design | Enhanced product traceability |

| Fully Automated Bottling Line | 99 | 1000 | Robust construction, Minimal manual intervention | Achieved zero downtime during operation |