+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

In today's fast-paced business environment, efficiency and precision are paramount, especially in production lines where labeling plays a crucial role in product identification and compliance. High-Speed Automatic Label Applicators have emerged as indispensable tools for manufacturers aiming to enhance productivity while maintaining high-quality standards. According to a recent report by MarketsandMarkets, the global labeling equipment market is projected to reach $5.1 billion by 2025, growing at a CAGR of 6.5%. This rapid growth underscores the increasing reliance on automation to meet consumer demand and streamline operations.

When choosing High-Speed Automatic Label Applicators, businesses must consider various factors that influence performance and integration into existing workflows. Reports from industry analysts highlight that companies employing advanced labeling solutions can reduce operational costs by up to 20%, while also improving accuracy and reducing labeling errors. As competitive pressures mount, investing in the right label applicator technology becomes essential for businesses looking to optimize their supply chain and boost overall efficiency. Understanding the key elements to evaluate when selecting these sophisticated machines is critical for achieving strategic operational goals.

When selecting high-speed automatic label applicators, it's crucial to have a clear understanding of your labeling needs and business requirements. Begin by assessing the types of products you will be labeling. Consider various factors such as the shape, size, and texture of your packaging. Different applicators excel at handling specific products; for example, some are better suited for cylindrical containers, while others might be designed for flat surfaces. Knowing the characteristics of your products will help you narrow down your choices and ensure compatibility.

Another important factor to evaluate is the volume of products you need to label. High-speed applicators vary significantly in their output capabilities. If your business requires high throughput for a fast-paced production line, investing in a machine that can handle larger quantities efficiently is essential. Conversely, if your production volume is lower or varies significantly, selecting a more flexible and adaptable applicator may be a better fit. Additionally, consider the ease of use and the maintenance requirements of the machine, as these can impact operational efficiency and overall productivity.

| Feature | Description | Importance | Considerations |

|---|---|---|---|

| Speed | Number of labels applied per minute | High | Must match production rate |

| Application Method | Type of dispensing and applying labels (e.g., wipe-on, blow-on) | Medium | Depends on product shape and surface |

| Label Size Compatibility | Range of label sizes that can be applied | High | Ensure it fits your label dimensions |

| Ease of Use | User-friendly controls and maintenance | Medium | Consider training requirements for staff |

| Integration | Ability to interface with existing production line | High | Assess compatibility with current systems |

| Durability | Reliability under continuous operation | High | Check warranty and maintenance support |

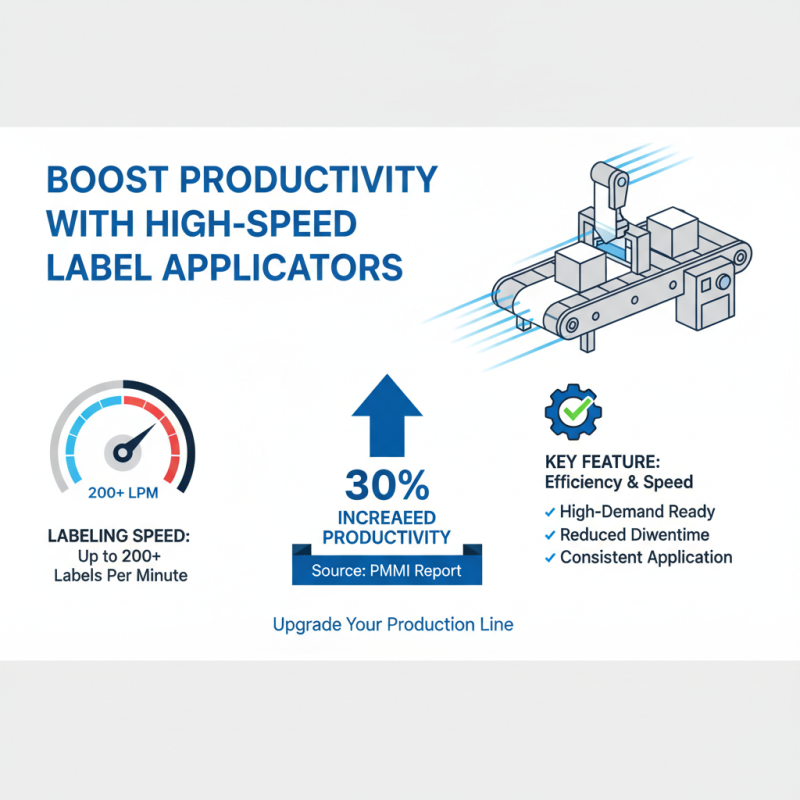

When selecting high-speed automatic label applicators for your business, it's essential to prioritize specific features that enhance efficiency and productivity. A recent report by the Packaging Machinery Manufacturers Institute (PMMI) indicates that companies can achieve up to 30% increased productivity by integrating high-speed applicators into their production lines. Therefore, one of the key features to look for is the applicator's labeling speed, which is typically measured in labels per minute (lpm). High-performance models can apply labels at speeds exceeding 200 lpm, allowing businesses to keep pace with high-demand environments.

Another critical aspect is the versatility of the applicator. Modern high-speed label applicators should accommodate a range of label sizes and materials, adapting seamlessly to various packaging types. A survey conducted by the Association for Packaging and Processing Technologies found that 75% of manufacturers prioritize flexibility in labeling systems to reduce changeover times. Additionally, features such as user-friendly interfaces and automated calibration processes can significantly lower the risk of human error while optimizing machine output. Investing in an applicator with these functionalities not only enhances operational efficiency but also leads to higher product consistency and quality in the long run.

When evaluating different types of label applicators for your business, it's essential to consider the specific needs of your production line. One crucial factor is the speed and efficiency of the applicator. High-speed models are designed to handle large volumes of products quickly, and they come equipped with advanced technology that enables precise labeling, reducing the chances of errors that could lead to costly recalls or customer dissatisfaction. Understanding the maximum output capacity and the speed at which the machine can operate will help you choose a model that aligns with your production requirements.

Another important aspect to evaluate is the compatibility of the label applicator with various label types and sizes. Some models are more versatile, accommodating a range of label materials, while others may be specialized for specific formats. Assessing the dimensions of the labels you plan to use and whether the applicator can handle different shapes and designs is vital. Additionally, consider the ease of integrating the applicator into your existing production line, as well as the maintenance and support required to keep it running smoothly. By thoroughly examining these factors, you can make an informed decision that will enhance your labeling efficiency and overall operational productivity.

This chart represents crucial evaluation metrics for high-speed automatic label applicators. The metrics include Speed (in labels per minute), Precision (as a percentage), Compatibility with different substrates, Ease of Use on a scale from 1 to 5, and Cost in dollars. These factors are essential for businesses when choosing an appropriate label applicator.

When contemplating the purchase of high-speed automatic label applicators, one of the most critical considerations is the balance between cost and return on investment (ROI). The initial expenditure for these machines can be substantial, often leading businesses to question their financial viability. To assess ROI effectively, it is essential to analyze both immediate savings and long-term gains. A well-selected label applicator can dramatically increase production efficiency, reduce manual labor costs, and minimize errors associated with labeling, all of which contribute to a healthier bottom line.

Additionally, businesses should evaluate the machine's impact on overall operational workflows. Automatic label applicators often enable faster processing times, which directly correlates to an increase in throughput. This boost in productivity not only enhances customer satisfaction through timely deliveries but may also attract new clients due to improved service levels. Companies should also consider factors such as maintenance costs, energy efficiency, and the potential for scalability, as these aspects can significantly affect the long-term ROI. By thoroughly analyzing these components, businesses can make informed decisions that not only meet their current labeling needs but also position them for future growth.

When selecting high-speed automatic label applicators for your business, maintenance and support considerations are critical for ensuring long-term operational effectiveness. Regular maintenance not only extends the lifespan of the applicators but also optimizes their performance. According to a report by the Packaging Machinery Manufacturers Institute, businesses that implement routine maintenance schedules can reduce breakdown occurrences by up to 30%, significantly decreasing production downtime.

It’s essential to choose a label applicator that offers robust customer support and readily available replacement parts. A comprehensive service agreement can enhance your operational resilience, allowing for quick resolution of any technical issues that may arise. Research indicates that about 40% of manufacturers report greater efficiency when supported by responsive technical assistance, as it minimizes disruption and ensures that production runs smoothly.

Tip: Ensure that you understand the maintenance requirements of the equipment before purchase. Familiarity with cleaning protocols, required spare parts, and service intervals can inform your choice and prevent unexpected costs down the line. Additionally, investing in training for your team on proper usage and minor troubleshooting can substantively improve the longevity and reliability of your applicators.