+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

In the fast-paced beverage industry, efficiency is key. Labeling machines for bottles play a crucial role in increasing productivity. According to recent industry reports, the global labeling machine market is expected to grow at a CAGR of 5.8% from 2022 to 2027. This growth highlights the rising demand for automated labeling solutions.

Investing in high-quality labeling machines for bottles can enhance brand visibility. A well-labeled bottle attracts consumer attention. However, choosing the right machine is often a challenge. Many companies struggle to find the perfect fit for their needs. Factors such as bottle shape, label type, and production speed should be carefully considered.

While many machines promise efficiency, not all live up to expectations. A careful analysis of various options is essential. Companies must assess their unique requirements to avoid wasting resources. Ultimately, selecting the right labeling machine is critical in a competitive market. It can define a brand’s success and influence consumer choices.

Labeling machines for bottles play a crucial role in packaging. These devices come in various types. Each one serves a unique purpose, tailored to different production needs. Some machines apply labels automatically, while others require manual intervention. Understanding the differences can help businesses choose the right one.

A reliable labeling machine should ensure accuracy and efficiency. The speed of labeling can impact overall production time. It's vital to consider the machine's compatibility with different bottle sizes and shapes. Not all machines can handle unusual designs. Sometimes, achieving a perfect label placement might be challenging. Misalignment can occur, and adjustments are necessary.

Customization is also an important factor. Some businesses need specific features like barcode printing. A machine that doesn't meet these requirements can hinder operations. Regular maintenance is essential, too. Neglecting this can lead to downtime and increased costs. Evaluating these elements can lead to better decisions for packaging processes.

When selecting a bottle labeling machine, several key features demand attention. Speed is critical. A machine that can apply labels quickly helps enhance productivity. Look for models that can handle various bottle sizes. A versatile machine can adapt to different formats, which saves time during production runs.

Precision is another essential factor. An accurate application reduces waste and enhances the product's appearance. Machines that offer adjustable labeling angles allow for better alignment and adherence. Additionally, ease of use is vital. Operators should quickly understand the controls, preventing long training sessions.

Maintenance should not be overlooked. Regular cleaning and easy access to parts make upkeep manageable. Machines that require complicated disassembly for routine maintenance might lead to operational downtime. Lastly, consider the machine’s durability. A sturdy machine can withstand daily pressures. Reflection on these aspects can lead to more effective decision-making when investing in labeling equipment.

When searching for the right bottle labeling machine, the choices can be overwhelming. Various reports indicate that nearly 30% of businesses struggle with inefficient labeling processes. This can lead to increased costs and reduced productivity. There are several machines on the market that cater to different needs, from small startups to large manufacturers.

Consider machines that offer flexibility and speed. A quality machine should label at least 30 bottles per minute. However, some options may require frequent adjustments, which can be a hassle. Data suggests that incorporating automated systems can reduce errors by about 15%. This means fewer mislabeled products and fewer returns.

Another important factor is the machine’s compatibility with varied bottle shapes and sizes. Many industries require custom solutions that standard machines cannot address. Regularly updating equipment based on production needs is essential. User reviews often highlight the need for intuitive controls as a crucial feature, but some machines still fall short in this area. Overall, picking the right labeling machine is essential for operational efficiency.

| Model | Labeling Speed (Bottles/min) | Label Width (mm) | Label Height (mm) | Price Range (USD) |

|---|---|---|---|---|

| Model A | 40 | 100 | 150 | $1,000 - $1,500 |

| Model B | 50 | 120 | 170 | $1,200 - $1,800 |

| Model C | 30 | 80 | 130 | $800 - $1,200 |

| Model D | 60 | 140 | 160 | $1,500 - $2,000 |

| Model E | 45 | 100 | 150 | $1,000 - $1,400 |

| Model F | 37 | 90 | 140 | $750 - $1,050 |

| Model G | 55 | 130 | 175 | $1,200 - $1,700 |

| Model H | 65 | 150 | 200 | $1,800 - $2,400 |

| Model I | 32 | 70 | 120 | $600 - $900 |

| Model J | 42 | 110 | 165 | $950 - $1,300 |

Choosing the right labeling machine for bottles can be overwhelming. There are various options available, each with unique features. Some machines offer high-speed operation, which is great for large volumes. Others prioritize precision, ensuring labels are applied perfectly every time. It's essential to understand your specific needs before making a decision.

When conducting a comparative analysis of labeling machines, consider factors like ease of use and maintenance. Some machines are more user-friendly, allowing quicker setup and adjustments. However, others may require technical expertise. Durability is another crucial element; machines should endure frequent use without significant wear. Investing in a reliable option can save costs in the long run.

Evaluate the price-to-performance ratio as well. Budget machines may lack essential features, leading to future frustrations. On the other hand, high-end models could have more functionalities than needed, which can be wasteful. Balancing cost with your operational requirements will help you make a more informed choice. Emphasize testing different machines, if possible, to gather real-world insights.

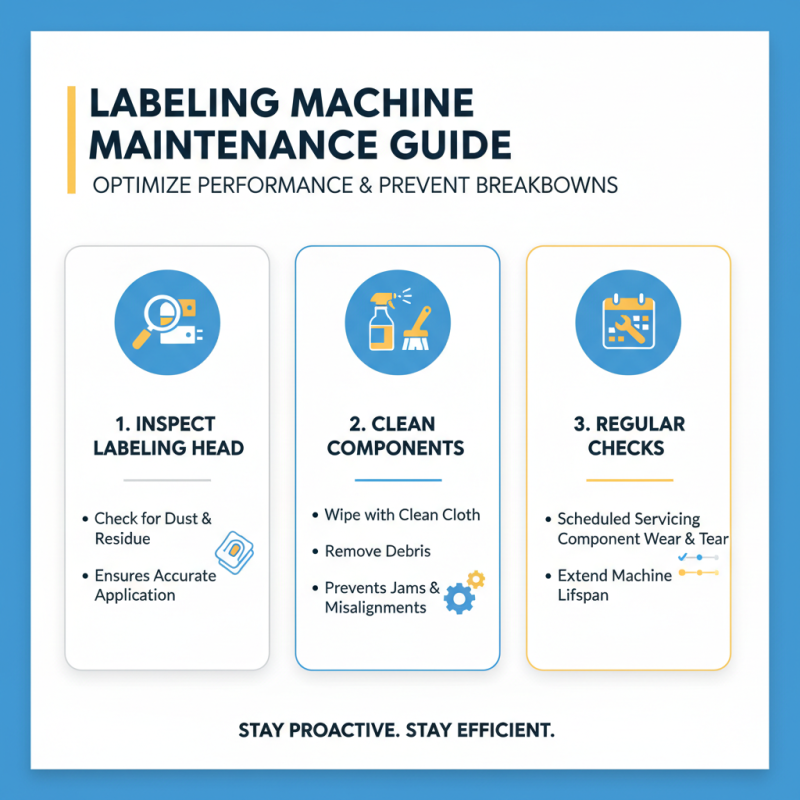

Proper maintenance is crucial for optimizing the performance of labeling machines. Regular checks on the machine’s components can prevent unexpected breakdowns. Start by inspecting the labeling head and ensure it is clean. Dust and residue can affect label application. A simple wipe with a clean cloth can often make a significant difference.

Lubrication is another vital aspect. Moving parts need lubrication to function smoothly. Use appropriate oils and follow the manufacturer’s guidance. Neglecting this task can lead to friction, causing parts to wear out prematurely. Furthermore, keep an eye on the tension of labels. If it’s too tight or too loose, it could lead to misalignment or jamming.

Training staff is essential for efficient operations. Ensure everyone understands how to handle the machine properly. Mistakes happen, such as overloading the machine with labels. These errors can lead to costly repairs. Encourage employees to report any irregularities immediately. Addressing small issues promptly can prevent bigger, more expensive problems in the future.