+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

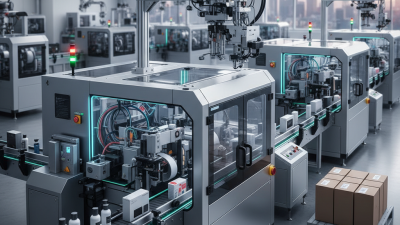

In the increasingly competitive landscape of packaging and logistics, the demand for efficient labeling solutions has surged. Self-Adhesive Label Applicators have emerged as indispensable tools in various industries, from food and beverage to pharmaceuticals. According to a recent study by Smithers Pira, the global market for self-adhesive labels is expected to reach $49 billion by 2024, reflecting a compound annual growth rate of 4.5%. This growth is driven by the rising need for accurate product information, regulatory compliance, and enhanced supply chain efficiency.

Industry expert Dr. Jane Holloway, a renowned authority on labeling technologies, emphasizes the importance of adopting innovative solutions: "In today's fast-paced market, companies cannot afford to overlook the efficiency provided by Self-Adhesive Label Applicators. They not only streamline processes but also significantly reduce labeling errors, thereby enhancing overall productivity." As businesses seek to improve operational effectiveness, understanding the applications and benefits of self-adhesive label applicators becomes crucial.

This guide aims to explore the various types of Self-Adhesive Label Applicators available, their applications across different sectors, and tips for selecting the right system to optimize your labeling operations. With the insights presented, businesses can make informed decisions that align with their operational goals and market demands.

Self-adhesive label applicators have become an essential tool in various industries,

streamlining the labeling process for a wide range of products. These devices eliminate the manual effort often associated

with label application, enhancing efficiency and reducing human error. According to a report by the Freedonia Group,

the demand for label applicators is projected to grow by over 4% annually, reflecting an increasing

recognition of automated solutions in manufacturing and logistics.

There are several types of self-adhesive label applicators available on the market,

each tailored to specific applications. For instance, tabletop label applicators are ideal for

small to medium production runs, where they provide quick and precise label placement on bottles and boxes. In contrast,

fully automatic applicators are designed for high-volume operations and can handle

diverse label sizes, making them suitable for large manufacturing settings. A study from Research and Markets

highlights that the global market for automatic label applicators is expected to surpass USD 1 billion

by 2026, driven by advancements in technology and an increasing emphasis on operational efficiency.

Understanding these various types is crucial for businesses aiming to optimize their production lines.

By investing in the right self-adhesive label applicator, companies can significantly decrease labeling times, enhance product presentation,

and ultimately improve their overall productivity, reflecting the ongoing trend of automation in the packaging industry.

When searching for the ideal self-adhesive label applicator, several key features should be prioritized to ensure efficiency and ease of use. First, the speed and precision of the applicator are crucial. A high-speed applicator can significantly enhance productivity, especially in environments with high-volume labeling needs. Additionally, precision in label placement prevents wastage and rework, making it essential to choose a model that offers accurate alignment and consistent application.

Another important feature to consider is the versatility of the applicator. Many operations require labels of various sizes and materials, so a model that can accommodate a range of label types can be extremely beneficial. Look for applicators with adjustable settings that allow for easy customization based on label dimensions. Furthermore, ease of operation and maintenance plays a vital role in the overall utility of the applicator. User-friendly controls and straightforward maintenance routines can save time and training costs, making the labeling process seamless and efficient for all operators involved.

In various industries, the demand for efficient labeling is paramount, as it directly influences productivity and accuracy in operations. Self-adhesive label applicators have emerged as a vital tool for businesses looking to enhance their labeling processes. These devices streamline the application of labels, reducing the time spent on manual labeling tasks, and minimizing errors. This technology is particularly beneficial in fast-paced environments such as manufacturing, food and beverage, and logistics. By automating label application, companies can achieve consistent labeling standards, ensuring that every product is accurately marked for tracking, compliance, and marketing purposes.

Moreover, label applicators cater to diverse industrial requirements, offering customizable solutions that improve workflows. In sectors like pharmaceuticals, where precise labeling is critical for safety and regulatory compliance, these applicators ensure labels are applied quickly without compromising on accuracy. In retail, they facilitate rapid preparation for inventory updates and promotions, allowing businesses to respond swiftly to market changes. With advancements in technology, many self-adhesive label applicators now feature integration capabilities, linking with existing inventory management systems to provide real-time tracking and inventory control. This synergy not only boosts operational efficiency but also empowers businesses to make informed decisions based on accurate data.

Investing in self-adhesive label applicators can yield significant benefits for businesses that require efficient and consistent labeling solutions. The initial cost of acquiring these machines may seem substantial, but a thorough cost-benefit analysis reveals that the long-term savings and productivity gains often outweigh the upfront investment. For example, by automating the labeling process, companies can dramatically reduce labor costs associated with manual application, while simultaneously improving accuracy and reducing waste from misapplied labels.

Furthermore, self-adhesive label applicators enhance operational efficiency by speeding up merchandise preparation and distribution processes. This increase in throughput allows businesses to maintain better inventory control and meet customer demands more promptly. In industries where time is a critical factor, the return on investment becomes evident, as faster processing times contribute to higher sales volumes and improved customer satisfaction. Assessing the overall impact of label applicators on a company's operational costs reveals that they are not merely an expense, but rather a strategic investment that can lead to enhanced profitability and streamlined operations over time.

Maintaining self-adhesive label applicators is crucial for ensuring consistent performance and optimizing workflow efficiency. Regular maintenance not only extends the lifespan of the equipment but also significantly reduces downtime, which can lead to considerable cost savings. According to a recent report by the Labeling and Packaging Machinery Association, companies can save up to 30% on operational costs by adhering to a robust maintenance schedule. Ensuring that components like rollers, adjustments, and adhesive dispensing systems are clean and functioning properly is essential for minimizing errors and maximizing productivity.

To further optimize label applicators, it's vital to evaluate the setup and alignment regularly. Misalignment can result in improper labeling, which affects product presentation and inventory accuracy. Industry studies indicate that an optimized labeling process can improve throughput by as much as 25%. Incorporating automated calibration systems can enhance precision and reduce human error. Additionally, training staff on the importance of proper maintenance practices and the correct operation of equipment not only fosters a culture of accountability but also empowers employees to take ownership of their roles in the labeling process, leading to higher overall efficiency in production workflows.

| Feature | Description | Best Practices | Optimization Tips |

|---|---|---|---|

| Speed | Application speed varies based on model | Regularly clean nozzle and adjust settings | Test different speeds for optimal performance |

| Accuracy | High precision is crucial for brand integrity | Utilize alignment guides | Frequent calibration checks |

| Usability | User-friendly design enhances workflow | Proper training for operators | Gather user feedback for improvements |

| Maintenance | Regular maintenance extends lifespan | Schedule periodic maintenance checks | Document maintenance history for reference |

| Compatibility | Supports various label types and sizes | Confirm compatibility before purchase | Keep an inventory of supported labels |

| Cost Efficiency | Reduce labor costs and increase output | Monitor operation costs regularly | Implement strategies to minimize waste |