+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

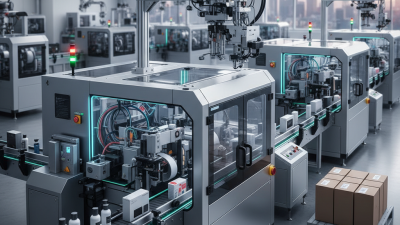

In the competitive landscape of modern business, choosing the right Precision Labeling and Packaging Machines is paramount. Industry expert John Smith emphasizes, “The right machinery can elevate product presentation and efficiency.” This insight highlights the importance of selecting equipment that aligns with specific operational needs.

When considering Precision Labeling and Packaging Machines, a variety of factors come into play. Businesses must evaluate the types of products they offer and the labeling requirements they have. A machine that excels in speed may lack precision, impacting overall quality. Companies should also assess their budget and long-term goals. This decision can significantly affect production capabilities.

Ultimately, the choice of labeling and packaging machinery is not straightforward. It requires careful consideration. Businesses may find themselves reflective about their priorities and the impact on their brand image. The right machinery can enhance productivity, but the wrong choice could lead to costly setbacks. Taking the time to analyze these machines is crucial for success in an increasingly demanding market.

When choosing precision labeling and packaging machines, understanding your specific needs is vital. Start by evaluating your product types and shapes. Different products require different labeling and packaging solutions. For instance, round bottles need specialized labeling techniques. Consider the materials you use, as they affect machine compatibility. Customization might be necessary.

Tips: Always have a few samples ready during consultations. Real products lead to better insights on your requirements. Don't shy away from asking for demonstrations. Observing machinery in action helps gauge efficiency and suitability.

Look into your production speed and volume. High-demand products need machines that can keep pace. If you have fluctuating demands, modular systems can adapt better. Have a clear idea of your budget. Quality machines can be costly, but they often save money in the long run.

Tips: Research maintenance costs. Machines require upkeep, and sometimes hidden costs arise. It's crucial to ask about warranties and support. Reflect on how the machine’s functionality aligns with your business growth. This alignment can influence your long-term success.

When evaluating different types of precision labeling and packaging machines, it's essential to focus on various factors. Efficiency, speed, and adaptability play crucial roles. According to industry reports, businesses can reduce labeling errors by 30% using automated machines. This claim underlines the importance of investing in reliable options.

Tip: Always assess the machine’s compatibility with your products. Some machines may not handle different package shapes effectively. Ensuring flexibility can save time and costs in the long run.

Durability is another essential aspect. Machines that fail often lead to production delays. A study highlights that 20% of downtime can be linked to equipment failure. This statistic should encourage businesses to opt for machines backed by strong warranty and service options.

Tip: Research maintenance costs before purchase. Sometimes cheaper machines incur higher long-term expenses. Failing to account for this could impact overall profitability.

Consider technology integration as well. Modern machines that connect with tracking systems improve operational visibility. However, not all companies are prepared for such advancements. A thoughtful approach can smooth the transition to new technology, minimizing disruptions.

When selecting precision labeling and packaging machines, several key features should be under consideration. Speed and efficiency are crucial. A machine that can handle high volumes without compromising accuracy will save time and costs. It’s essential to verify its output capacity. If your production increases, will the machine adapt? Many businesses overlook this aspect and face hurdles later.

Flexibility is another important factor. Your products may vary in size, shape, or material. The right machine should accommodate these differences seamlessly. A one-size-fits-all approach rarely works. Also, user-friendly interfaces enhance productivity. Employees should feel comfortable operating the machines. Complicated systems can lead to errors and wasted materials.

Consider the maintenance requirements, too. Machines that need constant servicing can disrupt operations. Some machinery may not provide necessary support, leading to frustrations. Regular maintenance is sometimes neglected, resulting in unexpected downtimes. Analyze the reliability of parts and ease of access for repairs. Also, ask yourself: is it easy to train new staff on this machine? Addressing these questions will guide you toward a better decision for your business.

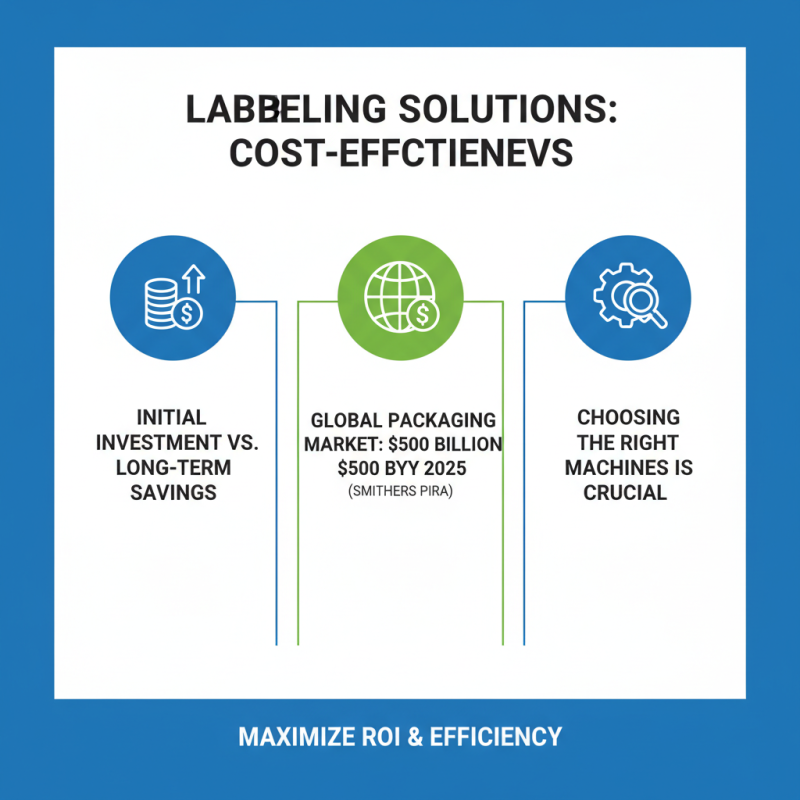

When assessing budget and cost-effectiveness for labeling solutions, businesses must evaluate initial investment and long-term savings. A report by Smithers Pira indicates that the global packaging market will reach $500 billion by 2025. Increasing demand makes choosing the right labeling machines crucial.

Many companies overlook hidden costs. Maintenance expenses can accumulate quickly. A poorly functioning machine can lead to downtime. According to a study by ResearchAndMarkets, poorly timed labeling can cost businesses up to $3 million annually in lost productivity. It’s essential to factor in maintenance, labor, and potential waste.

Moreover, businesses should understand ROI. Investing in high-efficiency machines can reduce material costs. The right machine can save 20% on materials. However, overlooking cheaper alternatives might seem appealing initially. These less efficient models can lead to greater expenses in the long run. It's a delicate balance between upfront costs and future savings.

Choosing precision labeling and packaging machines is crucial for your business's success. However, the support and service options from manufacturers play a significant role. Solid manufacturer support ensures your machines run smoothly. A responsive technical team can quickly address issues and minimize downtime. It’s vital to investigate the availability of service plans. Some manufacturers offer extended warranties, while others provide limited support.

Consider the training provided for your staff. A manufacturer that offers comprehensive training can improve efficiency. If employees struggle with machine operation, it can lead to costly mistakes. It’s also important to clarify spare parts availability. Delays in obtaining parts can disrupt production. Finding a manufacturer that guarantees quick shipping can save time.

Evaluate customer reviews about support experience. Some companies excel in customer service, while others may not. It’s essential to reflect on your priorities. Are you willing to wait for help? Or do you need immediate assistance? Your choice should align with your business needs. Proper research can lead to informed decisions, helping avoid future pitfalls.