+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

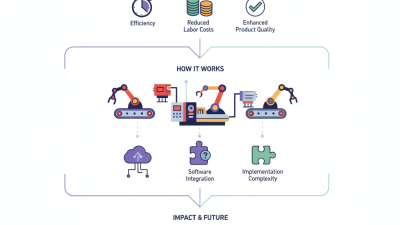

In the packaging industry, the importance of efficient labeling cannot be overstated. The Labeler Machine For Bottles is a vital tool for manufacturers. According to a report by Grand View Research, the global labeling machinery market was valued at over $40 billion in 2021. This figure is expected to grow steadily, indicating a strong demand for labeling solutions.

The Labeler Machine For Bottles automates the labeling process, increasing productivity. This machine helps in reducing human error and ensuring consistency in labels. It's essential for both small businesses and large-scale producers. Accurate labeling is crucial for compliance and brand recognition. An error in labeling can lead to significant losses, both financially and in consumer trust.

Despite its benefits, using a Labeler Machine For Bottles requires careful consideration. Operators must receive proper training to avoid mishaps. Additionally, ongoing maintenance is essential for optimal performance. Neglecting these aspects can result in downtime, negatively impacting production schedules. Understanding how this machine works is key to maximizing its efficiency and benefits.

Labeler machines for bottles play a crucial role in various industries. They ensure that products are properly labeled for consumer information and regulatory compliance. According to a recent industry report, the global labeling equipment market is expected to grow at a CAGR of over 5% from 2022 to 2027. This growth highlights the increasing need for efficiency in production lines.

These machines come in various types, each suited for specific labeling tasks. Some are semi-automatic, while others are fully automated. For instance, a rotary labeler can apply labels to hundreds of bottles per minute. However, not all machines guarantee perfect accuracy. Misalignment can occur, affecting the final product's presentation. Reports show that even leading manufacturers face challenges with label placement.

Another important aspect is maintenance. Labeler machines require regular upkeep to function smoothly. Bottles may jam, labels may tear, or ink may run out. These issues can lead to downtime in production, which can be costly. On average, downtime can reduce productivity by 20-30%. Companies must invest in reliable machines and ensure consistent training for operators.

Labeler machines are essential in the beverage industry. They ensure that each bottle is labeled correctly and efficiently. There are various types of labeler machines, each suited to different production needs. For instance, automatic labelers can label up to 600 bottles per minute, significantly boosting productivity. This efficiency can lead to a 15% increase in packaging output annually.

Bottle labeling can be divided into several categories. Pressure-sensitive labelers are among the most common. They apply labels using adhesive and allow for high-speed application with minimal downtime. Sleeve labelers, on the other hand, use heat to shrink labels around bottles, providing a more seamless look. Both types have their advantages, but they also come with challenges. For example, a misaligned label can halt production. This can lead to wasted materials and delays.

Adhesive quality is crucial for effective labeling. Inconsistent adhesive can affect the label's longevity and appearance. Industry reports indicate that nearly 20% of labels can fail due to poor adhesion. This highlights the need for rigorous quality checks. Considering these factors can improve labeling efficiency and reduce waste, which is vital in a competitive market.

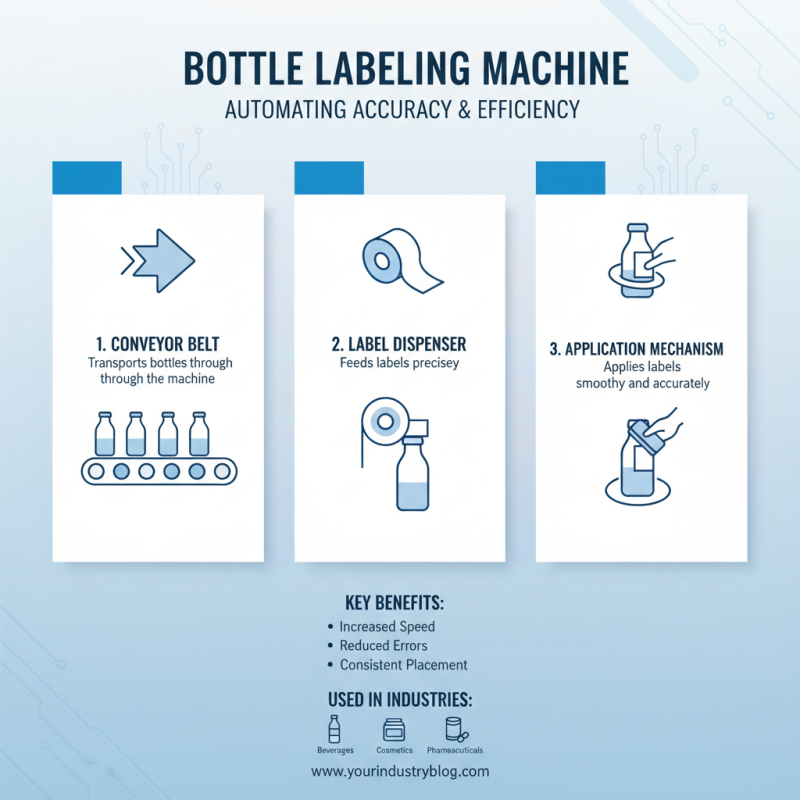

A bottle labeling machine is essential in various industries, from beverages to cosmetics. It automates the labeling process, ensuring accuracy and efficiency. The components of a bottle labeling machine include a conveyor belt, label dispenser, and application mechanism.

The conveyor belt moves bottles through different stages. Bottles are fed in a continuous flow. The label dispenser applies labels precisely, often using sensors for alignment. The application mechanism can vary; some machines use pressure-sensitive labels, while others rely on heat or glue.

**Tip:** Regular maintenance is crucial for optimal performance. Check components frequently to avoid malfunctions.

Additionally, some machines include a feedback system. This system monitors application accuracy. If the label is misaligned, the machine can automatically adjust. However, these systems may fail at times, leading to errors in labeling.

**Tip:** Always perform quality control checks after the labeling process. A small oversight can cause significant issues later on. Proper training for operators can save time and resources.

Operating a bottle labeler machine effectively requires understanding its key components and functions. These machines apply labels to various types of bottles, ensuring that they are securely placed and aligned. To start, ensure that the machine is properly set up. Adjust the conveyor belt speed and label placement settings for accuracy.

Tips for operating the machine effectively include regularly checking the label supply and the cutter's sharpness. A dull blade can create uneven edges and waste materials. Watch the label feed; occasional jams can occur if the labels are misaligned. This can be frustrating and time-consuming to fix.

Keep the machine clean to avoid residue build-up, which can hinder performance. Check the calibration often. If the labels don’t stick properly, re-evaluate the machine’s tension settings. It’s crucial to pay attention to detail. Missing labels or misaligned stickers can impact product presentation. Don’t rush through the process; take the time to ensure quality. Reflect on areas for improvement. Each run can teach something new.

Bottle labeling machines play a crucial role in various industries. These machines automate the labeling process, ensuring efficiency and accuracy. According to industry reports, the global bottle labeling machine market is projected to grow at a CAGR of 5.4% through 2026. This growth reflects the increasing demand for automated packaging solutions.

Common applications of bottle labeling machines include beverages, cosmetics, and pharmaceuticals. In the beverage industry, a well-positioned label is essential for branding. However, some companies struggle with label placement. Misalignment can lead to wasted materials and costs. In the cosmetic sector, eye-catching labels attract consumers. But, there is a challenge in maintaining quality, especially during high-volume runs.

Bottle labeling machines also offer significant benefits. They reduce labor costs and improve production speed. For instance, while manual labeling can take several hours, machines can complete the task in minutes. Yet, maintenance remains a concern. Malfunctions can lead to production delays. Regular checks are vital to ensure optimal performance. Balancing efficiency with reliability is an ongoing challenge for businesses.

| Application | Type of Labeling Machine | Speed (Bottles per Minute) | Benefits |

|---|---|---|---|

| Food and Beverage | Automatic Labeler | 100 | High efficiency, reduced labor costs |

| Cosmetics | Semi-Automatic Labeler | 50 | Flexibility, customizable labeling |

| Pharmaceuticals | Label Applicator | 150 | Ensures compliance, precision labeling |

| Household Products | Wrap-around Labeler | 80 | Efficient for various bottle shapes |

| Beverage Bottles | Top and Bottom Labeler | 70 | Enhances brand visibility, versatile |